Math Is Fun Forum

You are not logged in.

- Topics: Active | Unanswered

#1501 2022-09-13 14:19:30

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1474) Old age

Summary

Old age refers to ages nearing or surpassing the life expectancy of human beings, and is thus the end of the human life cycle. Terms and euphemisms for people at this age include old people, the elderly (worldwide usage), OAPs (British usage which stands for Old Age Pensioner), seniors, senior citizens (American usage), older adults (in the social sciences), and the elders (in many cultures).

Elderly people often have limited regenerative abilities and are more susceptible to disease, syndromes, injuries, and sickness than younger adults. A number of other disciplines and domains concern the aging and the aged, such as organic processes of aging (senescence), medical studies of the aging process (gerontology), diseases that afflict older adults (geriatrics), technology to support the aging society (gerontechnology), or leisure and sport activities adapted to older persons, such as senior sport. The elderly face various social issues concerning retirement, loneliness, and ageism.

Old age is not a definite biological stage, as the chronological age denoted as "old age" varies culturally and historically.

In 2011, the United Nations proposed a human rights convention that would specifically protect older people.

Details

Old age, also called senescence, in human beings, is the final stage of the normal life span. Definitions of old age are not consistent from the standpoints of biology, demography (conditions of mortality and morbidity), employment and retirement, and sociology. For statistical and public administrative purposes, however, old age is frequently defined as 60 or 65 years of age or older.

Old age has a dual definition. It is the last stage in the life processes of an individual, and it is an age group or generation comprising a segment of the oldest members of a population. The social aspects of old age are influenced by the relationship of the physiological effects of aging and the collective experiences and shared values of that generation to the particular organization of the society in which it exists.

There is no universally accepted age that is considered old among or within societies. Often discrepancies exist as to what age a society may consider old and what members in that society of that age and older may consider old. Moreover, biologists are not in agreement about the existence of an inherent biological cause for aging. However, in most contemporary Western countries, 60 or 65 is the age of eligibility for retirement and old-age social programs, although many countries and societies regard old age as occurring anywhere from the mid-40s to the 70s.

Social programs

State institutions to aid the elderly have existed in varying degrees since the time of the ancient Roman Empire. England in 1601 enacted the Poor Law, which recognized the state’s responsibility to the aged, although programs were carried out by local church parishes. An amendment to this law in 1834 instituted workhouses for the poor and aged, and in 1925 England introduced social insurance for the aged regulated by statistical evaluations. In 1940 programs for the aged came under England’s welfare state system.

In the 1880s Otto von Bismarck in Germany introduced old-age pensions whose model was followed by most other western European countries. Today more than 100 nations have some form of social security program for the aged. The United States was one of the last countries to institute such programs. Not until the Social Security Act of 1935 was formulated to relieve hardships caused by the Great Depression were the elderly granted old-age pensions. For the most part, these state programs, while alleviating some burdens of aging, still do not bring older people to a level of income comparable to that of younger people.

Physiological effects

The physiological effects of aging differ widely among individuals. However, chronic ailments, especially aches and pains, are more prevalent than acute ailments, requiring older people to spend more time and money on medical problems than younger people. The rising cost of medical care has caused a growing concern among older people and societies, in general resulting in constant reevaluation and reform of institutions and programs designed to aid the elderly with these expenses.

In ancient Rome and medieval Europe the average life span is estimated to have been between 20 and 30 years. Life expectancy today has expanded in historically unprecedented proportions, greatly increasing the numbers of people who survive over the age of 65. Therefore, the instances of medical problems associated with aging, such as certain kinds of cancer and heart disease, have increased, giving rise to greater consideration, both in research and in social programs, for accommodating this increase.

Certain aspects of sensory and perceptual skills, muscular strength, and certain kinds of memory tend to diminish with age, rendering older people unsuitable for some activities. There is, however, no conclusive evidence that intelligence deteriorates with age, but rather that it is more closely associated with education and standard of living. Sexual activity tends to decrease with age, but if an individual is healthy there is no age limit for its continuance.

Many of the myths surrounding the process of aging are being invalidated by increased studies in gerontology, but there still is not sufficient information to provide adequate conclusions.

Demographic and socioeconomic influences

In general the social status of an age group is related to its effective influence in its society, which is associated with that group’s function in productivity. In agrarian societies the elderly have a status of respectability. Their life experiences and knowledge are regarded as valuable, especially in preliterate societies where knowledge is orally transmitted. The range of activities in these societies allows the elderly to continue to be productive members of their communities.

In industrialized nations the status of the elderly has altered as the socioeconomic conditions have changed, tending to reduce the status of the elderly as a society becomes more technologically oriented. Since physical disability is less a factor in productive capability in industrialized countries, this reduction in social status is thought to have been generated by several interrelated factors: the numbers of still able-bodied older workers outstripping the number of available employment opportunities, the decline in self-employment which allows a worker to gradually decrease activity with age, and the continual introduction of new technology requiring special training and education.

Although in certain fields old age is still considered an asset, particularly in the political arena, older people are increasingly being forced into retirement before their productive years are over, causing problems in their psychological adaptations to old age. Retirement is not regarded unfavourably in all instances, but its economic limitations tend to further remove older people from the realm of influence and raise problems in the extended use of leisure time and housing. As a consequence, financial preparation for retirement has become an increased concern for individuals and society. For an essay on retirement, medical care, and other issues affecting the elderly, see John Kenneth Galbraith’s Notes on Aging, a Britannica sidebar by the distinguished economist, ambassador, and public servant.

Familial relationships tend to be the focus of the elderly’s attention. However, as the family structure in industrialized countries has changed in the past 100 years from a unit encompassing several generations living in close proximity to self-contained nuclear families of only parents and young children, older people have become isolated from younger people and each other. Studies have shown that as a person ages he or she prefers to remain in the same locale. However, the tendency for young people in industrialized countries to be highly mobile has forced older people to decide whether to move to keep up with their families or to remain in neighbourhoods which also change, altering their familiar patterns of activity. Although most older people do live within an hour from their closest child, industrialized societies are faced with formulating programs to accommodate increasing numbers of older people who function independently of their families.

A significant factor in the social aspects of old age concerns the values and education of the generation itself. In industrialized countries especially, where changes occur more rapidly than in agrarian societies, a generation born 65 years ago may find that the dominant mores, expectations, definitions of the quality of life, and roles of older people have changed considerably by the time it reaches old age. Formal education, which usually takes place in the early years and forms collective opinions and mores, tends to enhance the difficulties in adapting to old age. However, resistance to change, which is often associated with the elderly, is being shown to be less an inability to change than a trend in older people to regard life with a tolerant attitude. Apparent passivity may actually be a choice based on experience, which has taught older people to perceive certain aspects of life as unchangeable. Adult education programs are beginning to close the generation gap; however, as each successive generation reaches old age, bringing with it its particular biases and preferences, new problems arise requiring new social accommodations.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1502 2022-09-14 13:43:30

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1475) Crank (mechanism)

Summary

A crank is an arm attached at a right angle to a rotating shaft by which circular motion is imparted to or received from the shaft. When combined with a connecting rod, it can be used to convert circular motion into reciprocating motion, or vice versa. The arm may be a bent portion of the shaft, or a separate arm or disk attached to it. Attached to the end of the crank by a pivot is a rod, usually called a connecting rod (conrod).

The term often refers to a human-powered crank which is used to manually turn an axle, as in a bicycle crankset or a brace and bit drill. In this case a person's arm or leg serves as the connecting rod, applying reciprocating force to the crank. There is usually a bar perpendicular to the other end of the arm, often with a freely rotatable handle or pedal attached.

Details

Crank, in mechanics, is an arm secured at right angle to a shaft with which it can rotate or oscillate. Next to the wheel, the crank is the most important motion-transmitting device, since, with the connecting rod, it provides means for converting linear to rotary motion, and vice versa.

There are many conflicting claims concerning the origin of the crank, but it has been reasonably well established that the first recognizable crank appeared in China early in the 1st century AD. The first cranks had two right-angle bends and were hand-operated. The carpenter’s brace, invented about AD 1400 by a Flemish carpenter, may be considered the first complete crank, since it had four right-angle bends, with the arm and wrist of the operator forming the connecting rod.

The first mechanical connecting rods were used, it is said, on a treadle-operated machine in AD 1430. About this time flywheels were added to the rotating members to carry the members over the “dead” positions when the rod and the crank arm are lined up with each other (collinear).

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1503 2022-09-15 14:11:39

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1476) Hydrometer

Summary

A hydrometer or lactometer is an instrument used for measuring density or relative density of liquids based on the concept of buoyancy. They are typically calibrated and graduated with one or more scales such as specific gravity.

A hydrometer usually consists of a sealed hollow glass tube with a wider bottom portion for buoyancy, a ballast such as lead or mercury for stability, and a narrow stem with graduations for measuring. The liquid to test is poured into a tall container, often a graduated cylinder, and the hydrometer is gently lowered into the liquid until it floats freely. The point at which the surface of the liquid touches the stem of the hydrometer correlates to relative density. Hydrometers can contain any number of scales along the stem corresponding to properties correlating to the density.

Hydrometers are calibrated for different uses, such as a lactometer for measuring the density (creaminess) of milk, a saccharometer for measuring the density of sugar in a liquid, or an alcoholometer for measuring higher levels of alcohol in spirits.

The hydrometer makes use of Archimedes' principle: a solid suspended in a fluid is buoyed by a force equal to the weight of the fluid displaced by the submerged part of the suspended solid. The lower the density of the fluid, the deeper a hydrometer of a given weight sinks; the stem is calibrated to give a numerical reading.

Details

A hydrometer is an instrument used to determine specific gravity. It operates based on the Archimedes principle that a solid body displaces its own weight within a liquid in which it floats. Hydrometers can be divided into two general classes: liquids heavier than water and liquids lighter than water.

Hydrometer is a device for measuring some characteristics of a liquid, such as its density (weight per unit volume) or specific gravity (weight per unit volume compared with water). The device consists essentially of a weighted, sealed, long-necked glass bulb that is immersed in the liquid being measured; the depth of flotation gives an indication of liquid density, and the neck can be calibrated to read density, specific gravity, or some other related characteristic.

In practice, the floating glass bulb is usually inserted into a cylindrical glass tube equipped with a rubber ball at the top end for sucking liquid into the tube. Immersion depth of the bulb is calibrated to read the desired characteristic. A typical instrument is the storage-battery hydrometer, by means of which the specific gravity of the battery liquid can be measured and the condition of the battery determined. Another instrument is the radiator hydrometer, in which the float is calibrated in terms of the freezing point of the radiator solution. Others may be calibrated in terms of “proof ” of an alcohol solution or in terms of the percentage of sugar in a sugar solution.

The Baumé hydrometer, named for the French chemist Antoine Baumé, is calibrated to measure specific gravity on evenly spaced scales; one scale is for liquids heavier than water, and the other is for liquids lighter than water.

Additional Information

The gauge is a scientific tool, and it is used to measure the alcohol content present in the mash. The work of the device primarily measures liquid density in water relation. Distilling and brewing hydrometers make the two types of the hydrometers available. Their calibration is different, and that is why it is advisable to have both of them when making spirits. A brewing hydrometer should not be used when measuring the product to know the final proof; on the other hand, when making mash, you should not use spirit hydrometer. Here, we are going to talk about the hydrometers used for brewing, and the information is essential to brewers.

What Hydrometers Measure

The sugar amount present in the wash and mash is what mainly the brewing hydrometers measure. It will float depending on the amount of sugar that is in the mash. For instance, if it is high, the hydrometer will float higher. After fermentation takes place, the paste (the mash) becomes the wash and at this point, another reading is taken so as to know the amount of sugar that was turned into alcohol by the yeast. If the difference is big, then it means that the alcohol level in percentage is significant.

Many hydrometers have three scales and in this article, we are majorly looking at specific scale gravity.

* The Brix scale is in most times used to make wine.

* The Potential alcohol scale which estimates the alcohol in the mash

* The Specific Gravity scale which is useful for brewing

Original Gravity Determination

Determining original gravity is carried out so that the amount of sugar in the mash is known. Typically, this happens before fermentation takes place and before you add yeast to your mash. As we have already seen, the original gravity determines the amount of sugar that is contained in the pulp and gives an estimation of the amount of alcohol that is likely to be produced if the process does not go haywire.

There is a variation of the original gravity since it depends on the use of the recipe. Giving an example, corn whiskey which is popular among brewers starts at 1.055 and the production of wash and alcohol content ranges from 6% to 7.5%.

It is important that you take down the original gravity of the mash so that you can avoid forgetting. It is possible not to remember the reading by fermentation stage especially in a situation whereby you are carrying out many batches of fermentations at the same time. It is important to note that the first reading will not help you know the final alcohol content, and that is why another reading should be taken.

The original gravity reading is taken once the steps listed are completed.

* A beer sampler should be used and a jar filled with liquid to almost full.

* The wine hydrometer should then be dropped in a gentle manner into the pot. The hydrometer should be span in a way that it does not stick to the sides, and it will finally float.

* Take down the reading that you see on the barometer.

Determination of Final Gravity

The density of the liquid is measured by the final gravity like the original gravity. It should be noted that if the process continued without any problems, then the density of the liquid should be lower because the yeast ate the sugar present in the liquid during the process of fermentation. The alcohol content will be the difference between the original gravity and final gravity.

The steps given below are for the mash that has been fermented for one week. Meanwhile, if this is the case with your mash, the airlock seems to have fewer activities or even no activities going on. In case you notice there is a lot of bubbling then you should just wait since this means that there is work going on.

* Beer sampler should be used and a jar filled with liquid to almost full

* Slowly put the beer hydrometer into the jar and gently spin it ensuring that it does not stick to the far walls. It will float on the liquid.

* Take down the number seen on the hydrometer. The reading should be below 1.010, and if it exceeds this, then you should take your time and wait for some more days before taking another reading. It could be because the fermentation process is still going on. The readings should continuously be taken until it is constant and there is no change.

Reading the Hydrometer

The calibration of the hydrometer is at 60 degrees. There is the need to adjust it to actual reading in case you are taking a reading of your mash that is above 60 degrees. One can get help from online calculators so as to convert the readings taken either below or above 60 degrees.

Determination of Alcohol Content of Wash

So that you can be able to determine the alcohol concerning volume, then all you need is your original reading and final reading. Taking the example of what we did above the sample was 1.090 while it finally fermented to become 1.010. The math can simply be done as below;

Subtraction of Final Gravity from the original one

Multiplication of the difference by 131

1.090 minus 1.010 equals 0.08.

0.08 X 131= 10.48

The content of alcohol in the wash as seen in the above calculation is 10.48%

The Ideal Starting Alcohol Percentage For Wash

There are some instances where some recipes produce lower starting alcohol while some recipes produce higher starting alcohol. The combination of turbo yeast and a ton of sugar is what can lead to the production of starting alcohol percentage of even more than 20%. It is good to note that if you are after producing the best alcohol that has an excellent taste, the best recipes to use are those that have to start alcohol ranging from 5-8%. The alcohol produced will be around 10% or more of the content of alcohol.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1504 2022-09-16 14:28:49

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1477) Essential oil

Summary

An essential oil is a concentrated hydrophobic liquid containing volatile (easily evaporated at normal temperatures) chemical compounds from plants. Essential oils are also known as volatile oils, ethereal oils, aetheroleum, or simply as the oil of the plant from which they were extracted, such as oil of clove. An essential oil is essential in the sense that it contains the essence of the plant's fragrance—the characteristic fragrance of the plant from which it is derived. The term "essential" used here does not mean indispensable or usable by the human body, as with the terms essential amino acid or essential fatty acid, which are so called because they are nutritionally required by a living organism.

Essential oils are generally extracted by distillation, often by using steam. Other processes include expression, solvent extraction, sfumatura, absolute oil extraction, resin tapping, wax embedding, and cold pressing. They are used in perfumes, cosmetics, soaps, air fresheners and other products, for flavoring food and drink, and for adding scents to incense and household cleaning products.

Essential oils are often used for aromatherapy, a form of alternative medicine in which healing effects are ascribed to aromatic compounds. Aromatherapy may be useful to induce relaxation, but there is not sufficient evidence that essential oils can effectively treat any condition. Improper use of essential oils may cause harm including allergic reactions, inflammation and skin irritation. Children may be particularly susceptible to the toxic effects of improper use. Essential oils can be poisonous if ingested or absorbed through the skin.

Details

Essential oil is a highly volatile substance isolated by a physical process from an odoriferous plant of a single botanical species. The oil bears the name of the plant from which it is derived; for example, rose oil or peppermint oil. Such oils were called essential because they were thought to represent the very essence of odour and flavour.

Distillation is the most common method for isolation of essential oils, but other processes—including enfleurage (extraction by using fat), maceration, solvent extraction, and mechanical pressing—are used for certain products. Younger plants produce more oil than older ones, but old plants are richer in more resinous and darker oils because of the continuing evaporation of the lighter fractions of the oil.

Out of the vast number of plant species, essential oils have been well characterized and identified from only a few thousand plants. The oils are stored as microdroplets in glands of plants. After diffusing through the walls of the glands, the droplets spread over the surface of the plant before evaporating and filling the air with perfume. The most odoriferous plants are found in the tropics, where solar energy is greatest.

The function of the essential oil in a plant is not well understood. Odours of flowers probably aid in natural selection by acting as attractants for certain insects. Leaf oils, wood oils, and root oils may serve to protect against plant parasites or depredations by animals. Oleoresinous exudations that appear when the trunk of a tree is injured prevent loss of sap and act as a protective seal against parasites and disease organisms. Few essential oils are involved in plant metabolism, and some investigators maintain that many of these materials are simply waste products of plant biosynthesis.

Commercially, essential oils are used in three primary ways: as odorants they are used in cosmetics, perfumes, soaps, detergents, and miscellaneous industrial products ranging from animal feeds to insecticides to paints; as flavours they are present in bakery goods, candies, confections, meat, pickles, soft drinks, and many other food products; and as pharmaceuticals they appear in dental products and a wide, but diminishing, group of medicines.

The first records of essential oils come from ancient India, Persia, and Egypt; and both Greece and Rome conducted extensive trade in odoriferous oils and ointments with the countries of the Orient. Most probably these products were extracts prepared by placing flowers, roots, and leaves in fatty oils. In most ancient cultures, odorous plants or their resinous products were used directly. Only with the coming of the golden age of Arab culture was a technique developed for the distillation of essential oils. The Arabs were the first to distill ethyl alcohol from fermented sugar, thus providing a new solvent for the extraction of essential oils in place of the fatty oils that had probably been used for several millennia.

The knowledge of distillation spread to Europe during the Middle Ages, and isolation of essential oils by distillation was described during the 11th to 13th centuries. These distilled products became a specialty of the European medieval pharmacies, and by about 1500 the following products had been introduced: oils of cedarwood, calamus, costus, rose, rosemary, spike, incense, turpentine, sage, cinnamon, benzoin, and myrrh. The alchemical theories of the Swiss physician and alchemist Paracelsus played a role in stimulating physicians and pharmacists to seek essential oils from aromatic leaves, woods, and roots.

Starting from the time of Marco Polo, the much-prized spices of India, China, and the Indies served as the impetus for European trade with the Orient. Quite naturally, such spices as cardamom, sage, cinnamon, and nutmeg were subjected to the pharmacists’ stills. By the middle of the 18th century in Europe about 100 essential oils had been introduced, although there was little understanding about the nature of the products. As chemical knowledge expanded in the late 1800s and early 1900s, many well-known chemists took part in the chemical characterization of essential oils. Improvement in knowledge of essential oils led to a sharp expansion in production, and use of the volatile oils in medicine became quite subordinate to uses in foodstuffs, beverages, and perfumes.

In the United States, oils of turpentine and peppermint were produced before 1800; within the next several decades oils of four indigenous American plants became important commercially—namely, sassafras, wormwood, wintergreen, and sweet birch. Since 1800 many essential oils have been prepared, but only a few have attained commercial significance.

Methods of production

The first step in the isolation of essential oils is crushing or grinding the plant material to reduce the particle size and to rupture some of the cell walls of oil-bearing glands. Steam distillation is by far the most common and important method of production, and extraction with cold fat (enfleurage) or hot fat (maceration) is chiefly of historical importance.

Three different methods of steam distillation are practiced. In the oldest and simplest method a vessel containing water and the chopped or crushed plant material is heated by a direct flame, and the water vapour and volatile oil are recovered by a water-cooled condenser. This original method is being replaced by a process in which the plant material is suspended on a grid above the water level, and steam from a second vessel is introduced under the grid. The volatiles are condensed and the oil is separated. In the third process, the vessel containing the plant material on a grid is heated to prevent condensation of steam, so that dry distillation is attained.

In southern France essential oils were extracted with cold fat long before the introduction of extraction with volatile solvents. This process is applied to flowers that do not yield an appreciable quantity of oil by steam distillation or whose odour is changed by contact with boiling water and steam. In this process, flowers are spread over a highly purified mixture of tallow and lard and are left for a period varying from 24 hours to 72 hours. During this time most of the flower oil is absorbed by the fat. The petals are then removed (defleurage), and the process is repeated until the fat is saturated with oil. The final product is called pomade (e.g., pomade de jasmine).

In most cases, it is possible to shorten the long enfleurage process by extracting the essential oils using molten fat for one to two hours at a temperature ranging from about 45° to 80° C (110° to 175° F). The fat is filtered after each immersion, and after 10 to 20 extraction cycles the pomade is sold as such, or it may be extracted with alcohol to yield the oil residue.

Since both enfleurage and maceration are rather expensive processes, some essential-oil specialists have shifted almost completely to using volatile solvents for the recovery of essential oils from plant materials that could not be processed by steam distillation. Petroleum naphthas, benzene, and alcohol are the primary solvents.

A procedure called expression is applied only to citrus oils. The outer coloured peel is squeezed in presses, and the oil is decanted or centrifuged to separate water and cell debris. The method is used for oil of sweet and bitter orange, lemon, lime, mandarin, tangerine, bergamot, and grapefruit. Much oil is produced as a by-product of the concentrated-citrus-juice industry.

Chemical composition

Terpenes, organic compounds consisting of multiples of isoprene units (containing five carbon atoms), are by far the most dominant constituents of essential oils. Individual oils, however, may contain appreciable quantities of straight chain, aromatic, or heterocyclic compounds. Thus allyl sulfides are characteristics of oil of garlic, traces of indole and anthranilic acid esters are found in orange oil, straight chain alcohols and aldehydes are recognized in oil of violets, and phenols and other aromatic compounds are common to many oils.

Terpenes are built up from units of the simple five-carbon molecule isoprene. Both hydrocarbons and oxygenated compounds such as alcohols, aldehydes, ketones, acids, esters, oxides, lactones, acetals, and phenols are responsible for the characteristic odours and flavours.

In some oils one or only a few components predominate: thus oil of wintergreen contains about 98 percent of methyl salicylate; orange oil, about 90 percent of d-limonene; bois de rose, 90 percent of linalool; and cassia, up to 95 percent of cinnamaldehyde. In most oils there is a mixture of anywhere from a few dozen to several hundred individual compounds. Trace components are very important, since they give the oil a characteristic and natural odour.

Essential oils are generally expensive, with prices ranging from several U.S. dollars per kilogram on the low side to several thousand dollars per kilogram. The high price of the natural oils coupled with their limited availability has encouraged a search for substitutes. Great progress has been made in the synthesis of individual components such as geraniol, citral, linalyl acetate, and the like. These synthetics have been combined with natural oils to extend supplies, and they have also been blended together in an attempt to duplicate the oils themselves. Such reconstituted oils usually lack certain of the odour notes of the natural products, because of absence of trace ingredients, often unidentified, that may be present in the natural oils. They also tend to have a more “chemical” odour, because of trace impurities in the synthetics that are different from the components of natural oils.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1505 2022-09-17 13:41:00

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1478) Pine oil

Summary

Pine oil is an essential oil consisting of a colourless to light amber liquid of characteristic odour obtained from pine trees, or a synthetic oil similar in aroma and other properties. Pine oil is used as a solvent for gums, resins, and other substances. It has germicidal properties and is employed medically as a principal constituent of general disinfectants. It is also used in odorants, insecticides, detergents, wetting and emulsifying agents, wax preparations, and antifoaming agents and in textile scouring and the flotation process for refining lead and zinc ores.

Pitch-soaked wood of the pine tree, principally Pinus palustris but also certain other species of the family Pinaceae, is subjected to steam distillation, solvent extraction followed by steam distillation, or destructive distillation to obtain the pine oil, which boils at 200°–220° C (390°–430° F).

A variety of similar pine oils are obtained by distillation of cones and needles of various species of pines or by extraction from the stumps using solvents and steam. Synthetic pine oil is produced by conversion of terpene hydrocarbons into terpene alcohols.

Chemically, pine oils consist principally of cyclic terpene alcohols and are used in the manufacture of chemicals. Pine oil is insoluble in water but dissolves in alcohol and other organic solvents.

Details

Pine oil is an essential oil obtained from a variety of species of pine, particularly Pinus sylvestris. Typically, parts of the trees that are not used for lumber - stumps, etc. - are ground and subjected to steam distillation. As of 1995, synthetic pine oil was the "biggest single turpentine derivative." Synthetic pine oils accounted for 90% of sales as of 2000.

Composition

Pine oil is a higher boiling fraction from turpentine. Both synthetic and natural pine oil consists mainly of α-terpineol, a C10 alcohol (b.p. 214–217 °C). The detailed composition of natural pine oil depends on many factors, such as the species of the host plant. Synthetic pine oil is obtained by treating pinene with water in the presence of a catalytic amount of sulfuric acid. This treatment results in hydration of the alkene and rearrangement of the pinene skeleton, yielding terpineols.

Uses

Industrially, pine oil was once used in froth flotation for the separation of mineral from ores. For example, in copper extraction, pine oil is used to condition copper sulfide ores for froth flotation.

It is also used as a lubricant in small and expensive clockwork instruments.

In alternative medicine it is used in aromatherapy and as a scent in bath oils.

Properties as a disinfectant

Pine oil is used as a cleaning product, disinfectant, sanitizer, microbicide (or microbistat), virucide or insecticide. It is an effective herbicide where its action is to modify the waxy cuticle of plants, resulting in desiccation. Pine oil is a disinfectant that is mildly antiseptic. It is effective against Brevibacterium ammoniagenes, the fungi Candida albicans, Enterobacter aerogenes, Escherichia coli, Gram-negative enteric bacteria, household germs, Gram-negative household germs such as those causing salmonellosis, herpes simplex types 1 and 2, influenza type A, influenza virus type A/Brazil, influenza virus type A2/Japan, intestinal bacteria, Klebsiella pneumoniae, odor-causing bacteria, mold, mildew, Pseudomonas aeruginosa, Salmonella choleraesuis, Salmonella typhi, Salmonella typhosa, Serratia marcescens, Shigella sonnei, Staphylococcus aureus, Streptococcus faecalis, Streptococcus pyogenes, and Trichophyton mentagrophytes.

Safety

Pine oil has a relatively low human toxicity level, a low corrosion level and limited persistence; however, it irritates the skin and mucous membranes and has been known to cause breathing problems. Large doses may cause central nervous system depression.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1506 2022-09-18 14:24:09

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1479) Pediatrics

Summary

Pediatrics (also spelled paediatrics or pædiatrics) is the branch of medicine that involves the medical care of infants, children, adolescents, and young adults. In the United Kingdom, paediatrics covers many of their youth until the age of 18. The American Academy of Pediatrics recommends people seek pediatric care through the age of 21, but some pediatric subspecialists continue to care for adults up to 25. Worldwide age limits of pediatrics have been trending upward year after year. A medical doctor who specializes in this area is known as a pediatrician, or paediatrician. The word pediatrics and its cognates mean "healer of children," derived from the two Greek words: ("child") and (iatros "doctor, healer"). Pediatricians work in clinics, research centers, universities, general hospitals and children's hospitals, including those who practice pediatric subspecialties (e.g. neonatology requires resources available in a NICU).

Details

Pediatrics is the branch of medicine dealing with the health and medical care of infants, children, and adolescents from birth up to the age of 18. The word “paediatrics” means “healer of children”; they are derived from two Greek words: (pais = child) and (iatros = doctor or healer). Paediatrics is a relatively new medical specialty, developing only in the mid-19th century. Abraham Jacobi (1830–1919) is known as the father of paediatrics.

What does a pediatrician do?

A paediatrician is a child's physician who provides not only medical care for children who are acutely or chronically ill but also preventive health services for healthy children. A paediatrician manages physical, mental, and emotional well-being of the children under their care at every stage of development, in both sickness and health.

Aims of pediatrics

The aims of the study of paediatrics is to reduce infant and child rate of deaths, control the spread of infectious disease, promote healthy lifestyles for a long disease-free life and help ease the problems of children and adolescents with chronic conditions.

Paediatricians diagnose and treat several conditions among children including:-

* injuries

* infections

* genetic and congenital conditions

* cancers

* organ diseases and dysfunctions

Paediatrics is concerned not only about immediate management of the ill child but also long term effects on quality of life, disability and survival. Paediatricians are involved with the prevention, early detection, and management of problems including:-

* developmental delays and disorders

* behavioral problems

* functional disabilities

* social stresses

* mental disorders including depression and anxiety disorders

Collaboration with other specialists

Paediatrics is a collaborative specialty. Paediatricians need to work closely with other medical specialists and healthcare professionals and subspecialists of paediatrics to help children with problems.

How does pediatrics differ from adult medicine?

Paediatrics is different from adult medicine in more ways than one. The smaller body of an infant or neonate or a child is substantially different physiologically from that of an adult. So treating children is not like treating a miniature adult.

Congenital defects, genetic variance, and developmental issues are of greater concern to pediatricians than physicians treating adults. In addition, there are several legal issues in paediatrics. Children are minors and, in most jurisdictions, cannot make decisions for themselves. The issues of guardianship, privacy, legal responsibility and informed consent should be considered in every pediatric procedure.

Training

A paediatrician is a graduate from a medical school first. He or she being a primary care paediatrician then completes three years of education in an accredited pediatric residency program. They learn about caring for infant, child, adolescent, and young adults during this period.

Following the pediatric residency, the pediatrician is eligible for board certification by the American Board of Paediatrics with successful completion of a comprehensive written examination. Recertification is required every seven years.

Additional Information

Pediatrics is a medical specialty dealing with the development and care of children and with the diagnosis and treatment of childhood diseases. The first important review of childhood illness, an anonymous European work called The Children’s Practice, dates from the 12th century. The specialized focus of pediatrics did not begin to emerge in Europe until the 18th century. The first specialized children’s hospitals, such as the London Foundling Hospital, established in 1745, were opened at this time. These hospitals later became major centres for training in pediatrics, which began to be taught as a separate discipline in medical schools by the middle of the 19th century.

The major focus of early pediatrics was the treatment of infectious diseases that affected children. Thomas Sydenham in Britain had led the way with the first accurate descriptions of measles, scarlet fever, and other diseases in the 17th century. Clinical studies of childhood diseases proliferated throughout the 18th and 19th centuries, culminating in one of the first modern textbooks of pediatrics, published by Frédéric Rilliet and Antoine Barthez in France in 1838–43, but there was little that could be done to cure these diseases until the end of the 19th century. As childhood diseases came under control through the combined efforts of pediatricians, immunologists, and public-health workers, the focus of pediatrics began to change, and early in the 20th century the first well-child clinics were established to monitor and study the normal growth and development of children. By the mid-20th century, the use of antibiotics and vaccines had all but eliminated most serious infectious diseases of childhood in the developed world, and infant and child mortality had fallen to the lowest levels ever. In the last half of the century, pediatrics again expanded to incorporate the study of behavioral and social as well as specifically medical aspects of child health.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1507 2022-09-19 14:07:06

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

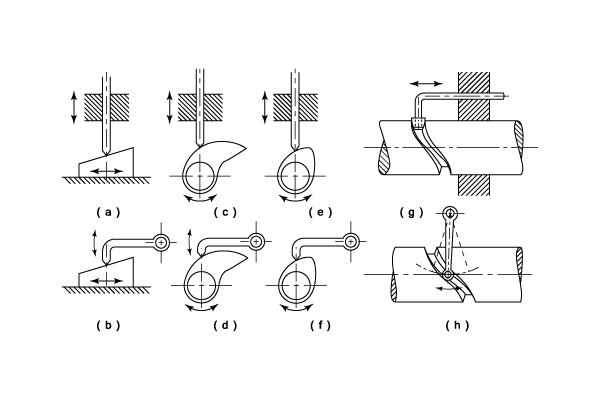

1480) Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion. It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path. The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an eccentric disc or other shape that produces a smooth reciprocating (back and forth) motion in the follower, which is a lever making contact with the cam. A cam timer is similar, and were widely used for electric machine control (an electromechanical timer in a washing machine being a common example) before the advent of inexpensive electronics, microcontrollers, integrated circuits, programmable logic controllers and digital control.

Camshaft

The cam can be seen as a device that converts rotational motion to reciprocating (or sometimes oscillating) motion. A common example is the camshaft of an automobile, which takes the rotary motion of the engine and converts it into the reciprocating motion necessary to operate the intake and exhaust valves of the cylinders.

Cams can be characterized by their displacement diagrams, which reflect the changing position a follower would make as the surface of the cam moves in contact with the follower. In the example shown, the cam rotates about an axis. These diagrams relate angular position, usually in degrees, to the radial displacement experienced at that position. Displacement diagrams are traditionally presented as graphs with non-negative values. The rise is the motion of the follower away from the cam center, dwell is the motion where the follower is at rest, and return is the motion of the follower toward the cam center.

A common type is in the valve actuators in internal combustion engines. Here, the cam profile is commonly symmetric and at rotational speeds generally met with, very high acceleration forces develop. Ideally, a convex curve between the onset and maximum position of lift reduces acceleration, but this requires impractically large shaft diameters relative to lift. Thus, in practice, the points at which lift begins and ends mean that a tangent to the base circle appears on the profile. This is continuous with a tangent to the tip circle. In designing the cam, the lift and the dwell angle θ are given. If the profile is treated as a large base circle and a small tip circle, joined by a common tangent, giving lift L, the relationship can be calculated, given the angle φ between one tangent and the axis of symmetry, while C is the distance between the centres of the circles (required), and R is the radius of the base (given) and r that of the tip circle (required).

Disc or plate cam

The most commonly used cam is the cam plate (also known as disc cam or radial cam) which is cut out of a piece of flat metal or plate. Here, the follower moves in a plane perpendicular to the axis of rotation of the camshaft.[8] Several key terms are relevant in such a construction of plate cams: base circle, prime circle (with radius equal to the sum of the follower radius and the base circle radius), pitch curve which is the radial curve traced out by applying the radial displacements away from the prime circle across all angles, and the lobe separation angle (LSA – the angle between two adjacent intake and exhaust cam lobes).

The base circle is the smallest circle that can be drawn to the cam profile.

A once common, but now outdated, application of this type of cam was automatic machine tool programming cams. Each tool movement or operation was controlled directly by one or more cams. Instructions for producing programming cams and cam generation data for the most common makes of machine, were included in engineering references well into the modern CNC era.

This type of cam is used in many simple electromechanical appliances controllers, such as dishwashers and clothes washing machines, to actuate mechanical switches that control the various parts.

Motorcycle transmission showing cylindrical cam with three followers. Each follower controls the position of a shift fork.

Cylindrical cam

A cylindrical cam or barrel cam is a cam in which the follower rides on the surface of a cylinder. In the most common type, the follower rides in a groove cut into the surface of a cylinder. These cams are principally used to convert rotational motion to linear motion parallel to the rotational axis of the cylinder. A cylinder may have several grooves cut into the surface and drive several followers. Cylindrical cams can provide motions that involve more than a single rotation of the cylinder and generally provide positive positioning, removing the need for a spring or other provision to keep the follower in contact with the control surface.

Applications include machine tool drives, such as reciprocating saws, and shift control barrels in sequential transmissions, such as on most modern motorcycles.

A special case of this cam is a constant lead, where the position of the follower is linear with rotation, as in a lead screw. The purpose and detail of implementation influence whether this application is called a cam or a screw thread, but in some cases, the nomenclature may be ambiguous.

Cylindrical cams may also be used to reference an output to two inputs, where one input is the rotation of the cylinder and the other is the position of the follower along the cam. The output is radial to the cylinder. These were once common for special functions in control systems, such as fire control mechanisms for guns on naval vessels and mechanical analog computers.

An example of a cylindrical cam with two inputs is provided by a duplicating lathe, an example of which is the Klotz axe handle lathe, which cuts an axe handle to a form controlled by a pattern acting as a cam for the lathe mechanism.

Face cam

A face cam produces motion by using a follower riding on the face of a disk. The most common type has the follower ride in a slot so that the captive follower produces radial motion with positive positioning without the need for a spring or other mechanism to keep the follower in contact with the control surface. A face cam of this type generally has only one slot for a follower on each face. In some applications, a single element, such as a gear, a barrel cam or other rotating element with a flat face, may do duty as a face cam in addition to other purposes.

Face cams may provide repetitive motion with a groove that forms a closed curve or may provide function generation with a stopped groove. Cams used for function generation may have grooves that require several revolutions to cover the complete function, and in this case, the function generally needs to be invertible so that the groove does not self intersect, and the function output value must differ enough at corresponding rotations that there is sufficient material separating the adjacent groove segments. A common form is the constant lead cam, where the displacement of the follower is linear with rotation, such as the scroll plate in a scroll chuck. Non-invertible functions, which require the groove to self-intersect, can be implemented using special follower designs.

A variant of the face cam provides motion parallel to the axis of cam rotation. A common example is the traditional sash window lock, where the cam is mounted to the top of the lower sash, and the follower is the hook on the upper sash. In this application, the cam is used to provide a mechanical advantage in forcing the window shut, and also provides a self-locking action, like some worm gears, due to friction.

Face cams may also be used to reference a single output to two inputs, typically where one input is the rotation of the cam and the other is the radial position of the follower. The output is parallel to the axis of the cam. These were once common is mechanical analog computation and special functions in control systems.

A face cam that implements three outputs for a single rotational input is the stereo phonograph, where a relatively constant lead groove guides the stylus and tonearm unit, acting as either a rocker-type (tonearm) or linear (linear tracking turntable) follower, and the stylus alone acting as the follower for two orthogonal outputs to representing the audio signals. These motions are in a plane radial to the rotation of the record and at angles of 45 degrees to the plane of the disk (normal to the groove faces). The position of the tonearm was used by some turntables as a control input, such as to turn the unit off or to load the next disk in a stack, but was ignored in simple units.

Heart shaped cam

This type of cam, in the form of a symmetric heart, is used to return a shaft holding the cam to a set position by pressure from a roller. They were used on early models of Post Office Master clocks to synchronise the clock time with Greenwich Mean Time when the activating follower was pressed onto the cam automatically via a signal from an accurate time source.

Snail drop cam

This type of cam was used for example in mechanical timekeeping clocking-in clocks to drive the day advance mechanism at precisely midnight and consisted of a follower being raised over 24 hours by the cam in a spiral path which terminated at a sharp cut off at which the follower would drop down and activate the day advance. Where timing accuracy is required as in clocking-in clocks these were typically ingeniously arranged to have a roller cam follower to raise the drop weight for most of its journey to near its full height, and only for the last portion of its travel for the weight to be taken over and supported by a solid follower with a sharp edge. This ensured that the weight dropped at a precise moment, enabling accurate timing. This was achieved by the use of two snail cams mounted coaxially with the roller initially resting on one cam and the final solid follower on the other but not in contact with its cam profile. Thus the roller cam initially carried the weight, until at the final portion of the run the profile of the non-roller cam rose more than the other causing the solid follower to take the weight.

Linear cam

A linear cam is one in which the cam element moves in a straight line rather than rotates. The cam element is often a plate or block but may be any cross-section. The key feature is that the input is a linear motion rather than rotational. The cam profile may be cut into one or more edges of a plate or block, may be one or more slots or grooves in the face of an element, or may even be a surface profile for a cam with more than one input. The development of a linear cam is similar to, but not identical to, that of a rotating cam.

A common example of a linear cam is a key for a pin tumbler lock. The pins act as followers. This behavior is exemplified when the key is duplicated in a key duplication machine, where the original key acts as a control cam for cutting the new key.

History

Cam mechanisms appeared in China at around 600 BC in the form of a crossbow trigger-mechanism with a cam-shaped swing arm. However, the trigger mechanism did not rotate around its own axis and traditional Chinese technology generally made little use of continuously rotating cams. Nevertheless, later research showed that such cam mechanisms did in fact rotate around its own axis. Likewise, more recent research indicates that cams were used in water-driven trip hammers by the latter half of the Western Han Dynasty (206 BC – 8 AD) as recorded in the Huan Zi Xin Lun. Complex pestles were also mentioned in later records such as the Jin Zhu Gong Zan and the Tian Gong Kai Wu, amongst many other records of water-driven pestles. During the Tang dynasty, the wooden clock within the water-driven astronoical device, the spurs inside a water-driven armillary sphere, the automated alarm within a five-wheeled sand-driven clock, artificial paper figurines within a revolving lantern, all utilized cam mechanisms. The Chinese hodometer which utilized a bell and gong mechanism is also a cam, as described in the Song Shi. In the book Nongshu, the vertical wheel of a water-driven wind box is also a cam. Out of these examples, the water-driven pestle and the water driven wind box both have two cam mechanisms inside. Cams that rotated continuously and functioned as integral machine elements were built into Hellenistic water-driven automata from the 3rd century BC. The cam and camshaft later appeared in mechanisms by Al-Jazari and Shooshtari, who used them in their automata, described in 1206. The cam and camshaft appeared in European mechanisms from the 14th century. Waldo J Kelleigh of Electrical Apparatus Company patented the adjustable cam in the United States in 1956 for its use in mechanical engineering and weaponry.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1508 2022-09-20 13:32:12

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1481) Barometer

Summary

A barometer is a device used to measure atmospheric pressure. Because atmospheric pressure changes with distance above or below sea level, a barometer can also be used to measure altitude. There are two main types of barometers: mercury and aneroid.

In the mercury barometer, atmospheric pressure balances a column of mercury, the height of which can be precisely measured. To increase their accuracy, mercury barometers are often corrected for ambient temperature and the local value of gravity. Common pressure units include pounds per square inch; dynes per square centimetre; newtons per square metre (the SI unit called the pascal); inches, centimetres, or millimetres of mercury; and millibars (1 millibar equals 1,000 dynes per square centimetre, 100 pascals, or 0.75 millimetre of mercury). Atmospheric pressure at sea level is about 14.7 pounds per square inch, equivalent to 30 inches (760 millimetres) of mercury, 1,013.2 millibars, or 101,320 pascals.

Of the many different varieties of mercury barometers, most variations arise from different techniques for measuring the height of the mercury column. Though other liquids can be used in a barometer, mercury is the most common. Its density allows the vertical column of the barometer to be of manageable size. If water were used, for instance, the column would have to be 34 feet high.

A nonliquid barometer called the aneroid barometer is widely used in portable instruments and in aircraft altimeters because of its smaller size and convenience. It contains a flexible-walled evacuated capsule, the wall of which deflects with changes in atmospheric pressure. This deflection is coupled mechanically to an indicating needle. A mercury barometer is used to calibrate and check aneroid barometers. Calibration can be, for example, in terms of atmospheric pressure or altitude above sea level. The concept of altitude above sea level, based on barometric pressure, is used to create one type of aircraft altimeter.

A barometer that mechanically records changes in barometric pressure over time is called a barograph. Though mercury barographs have been made, aneroid barographs are much more common. The motion of the aneroid capsule is magnified through levers to drive a recording pen. The pen traces a line on a graph that is usually wrapped around a cylinder driven by a clockwork mechanism.

Details

A barometer is a scientific instrument that is used to measure air pressure in a certain environment. Pressure tendency can forecast short term changes in the weather. Many measurements of air pressure are used within surface weather analysis to help find surface troughs, pressure systems and frontal boundaries.

Barometers and pressure altimeters (the most basic and common type of altimeter) are essentially the same instrument, but used for different purposes. An altimeter is intended to be used at different levels matching the corresponding atmospheric pressure to the altitude, while a barometer is kept at the same level and measures subtle pressure changes caused by weather and elements of weather. The average atmospheric pressure on the earth's surface varies between 940 and 1040 hPa (mbar). The average atmospheric pressure at sea level is 1013 hPa (mbar).

Types:

Water barometers

The concept that decreasing atmospheric pressure predicts stormy weather, postulated by Lucien Vidi, provides the theoretical basis for a weather prediction device called a "weather glass" or a "Goethe barometer" (named for Johann Wolfgang von Goethe, the renowned German writer and polymath who developed a simple but effective weather ball barometer using the principles developed by Torricelli). The French name, le baromètre Liègeois, is used by some English speakers. This name reflects the origins of many early weather glasses – the glass blowers of Liège, Belgium.

The weather ball barometer consists of a glass container with a sealed body, half filled with water. A narrow spout connects to the body below the water level and rises above the water level. The narrow spout is open to the atmosphere. When the air pressure is lower than it was at the time the body was sealed, the water level in the spout will rise above the water level in the body; when the air pressure is higher, the water level in the spout will drop below the water level in the body. A variation of this type of barometer can be easily made at home.

Mercury barometers

A mercury barometer is an instrument used to measure atmospheric pressure in a certain location and has a vertical glass tube closed at the top sitting in an open mercury-filled basin at the bottom. Mercury in the tube adjusts until the weight of it balances the atmospheric force exerted on the reservoir. High atmospheric pressure places more force on the reservoir, forcing mercury higher in the column. Low pressure allows the mercury to drop to a lower level in the column by lowering the force placed on the reservoir. Since higher temperature levels around the instrument will reduce the density of the mercury, the scale for reading the height of the mercury is adjusted to compensate for this effect. The tube has to be at least as long as the amount dipping in the mercury + head space + the maximum length of the column.

Torricelli documented that the height of the mercury in a barometer changed slightly each day and concluded that this was due to the changing pressure in the atmosphere. He wrote: "We live submerged at the bottom of an ocean of elementary air, which is known by incontestable experiments to have weight". Inspired by Torricelli, Otto von Guericke on 5 December 1660 found that air pressure was unusually low and predicted a storm, which occurred the next day.

Fortin barometer

The mercury barometer's design gives rise to the expression of atmospheric pressure in inches or millimeters of mercury (mmHg). A torr was originally defined as 1 mmHg. The pressure is quoted as the level of the mercury's height in the vertical column. Typically, atmospheric pressure is measured between 26.5 inches (670 mm) and 31.5 inches (800 mm) of Hg. One atmosphere (1 atm) is equivalent to 29.92 inches (760 mm) of mercury.

Design changes to make the instrument more sensitive, simpler to read, and easier to transport resulted in variations such as the basin, siphon, wheel, cistern, Fortin, multiple folded, stereometric, and balance barometers.

In 2007, a European Union directive was enacted to restrict the use of mercury in new measuring instruments intended for the general public, effectively ending the production of new mercury barometers in Europe. The repair and trade of antiques (produced before late 1957) remained unrestricted.

Fitzroy barometer

Fitzroy barometers combine the standard mercury barometer with a thermometer, as well as a guide of how to interpret pressure changes.

Fortin barometer

Fortin barometers use a variable displacement mercury cistern, usually constructed with a thumbscrew pressing on a leather diaphragm bottom (V in the diagram). This compensates for displacement of mercury in the column with varying pressure. To use a Fortin barometer, the level of mercury is set to zero by using the thumbscrew to make an ivory pointer (O in the diagram) just touch the surface of the mercury. The pressure is then read on the column by adjusting the vernier scale so that the mercury just touches the sightline at Z. Some models also employ a valve for closing the cistern, enabling the mercury column to be forced to the top of the column for transport. This prevents water-hammer damage to the column in transit.

Sympiesometer

A sympiesometer is a compact and lightweight barometer that was widely used on ships in the early 19th century. The sensitivity of this barometer was also used to measure altitude.

Sympiesometers have two parts. One is a traditional mercury thermometer that is needed to calculate the expansion or contraction of the fluid in the barometer. The other is the barometer, consisting of a J-shaped tube open at the lower end and closed at the top, with small reservoirs at both ends of the tube.

Wheel barometers

A wheel barometer uses a "J" tube sealed at the top of the longer limb. The shorter limb is open to the atmosphere and floating on top of the mercury there is a small glass float. A fine silken thread is attached to the float which passes up over a wheel and then back down to a counterweight (usually protected in another tube). The wheel turns the point on the front of the barometer. As atmospheric pressure increases mercury moves from the short to the long limb, the float falls and the pointer moves. When pressure increases the mercury moves back, lifting the float and turning the dial the other way.

Around 1810 the wheel barometer, which could be read from a great distance, became the first practical and commercial instrument favoured by farmers and the educated classes in the UK. The face of the barometer was circular with a simple dial pointing to an easily readable scale: "Rain - Change - Dry" with the "Change" at the top centre of the dial. Later models added a barometric scale with finer graduations "Stormy (28 inches of mercury), Much Rain (28.5), Rain (29), Change (29.5), Fair (30), Set fair (30.5), very dry(31)".

Natalo Aiano is recognised as one of the finest makers of wheel barometers, an early pioneer in a wave of artisanal Italian instrument and barometer makers that were encouraged to emigrate to the UK. He listed as working in Holborn, London c.1785-1805.[18] From 1770 onwards a large number of Italians came to England because they were accomplished glass blowers or instrument makers. By 1840 it was fair to say that the Italians dominated the industry in England.

Vacuum pump oil barometer

Using vacuum pump oil as the working fluid in a barometer has led to the creation of the new "World's Tallest Barometer" in February 2013. The barometer at Portland State University (PSU) uses doubly distilled vacuum pump oil and has a nominal height of about 12.4 m for the oil column height; expected excursions are in the range of ±0.4 m over the course of a year. Vacuum pump oil has very low vapour pressure and it is available in a range of densities; the lowest density vacuum oil was chosen for the PSU barometer to maximize the oil column height.[20]

Aneroid barometer

An aneroid barometer is an instrument used for measuring air pressure as a method that does not involve liquid. Invented in 1844 by French scientist Lucien Vidi, the aneroid barometer uses a small, flexible metal box called an aneroid cell (capsule), which is made from an alloy of beryllium and copper. The evacuated capsule (or usually several capsules, stacked to add up their movements) is prevented from collapsing by a strong spring. Small changes in external air pressure cause the cell to expand or contract. This expansion and contraction drives mechanical levers such that the tiny movements of the capsule are amplified and displayed on the face of the aneroid barometer. Many models include a manually set needle which is used to mark the current measurement so a change can be seen. This type of barometer is common in homes and in recreational boats. It is also used in meteorology, mostly in barographs and as a pressure instrument in radiosondes.

Barographs

A barograph is a recording aneroid barometer where the changes in atmospheric pressure are recorded on a paper chart.

The principle of the barograph is same as that of the aneroid barometer. Whereas the barometer displays the pressure on a dial, the barograph uses the small movements of the box to transmit by a system of levers to a recording arm that has at its extreme end either a scribe or a pen. A scribe records on smoked foil while a pen records on paper using ink, held in a nib. The recording material is mounted on a cylindrical drum which is rotated slowly by a clock. Commonly, the drum makes one revolution per day, per week, or per month and the rotation rate can often be selected by the user.

MEMS barometers

Microelectromechanical systems (or MEMS) barometers are extremely small devices between 1 and 100 micrometres in size (0.001 to 0.1 mm). They are created via photolithography or photochemical machining. Typical applications include miniaturized weather stations, electronic barometers and altimeters.

A barometer can also be found in smartphones such as the Samsung Galaxy Nexus, Samsung Galaxy S3-S6, Motorola Xoom, Apple iPhone 6 and newer iPhones, and Timex Expedition WS4 smartwatch, based on MEMS and piezoresistive pressure-sensing technologies. Inclusion of barometers on smartphones was originally intended to provide a faster GPS lock. However, third party researchers were unable to confirm additional GPS accuracy or lock speed due to barometric readings. The researchers suggest that the inclusion of barometers in smartphones may provide a solution for determining a user's elevation, but also suggest that several pitfalls must first be overcome.

More unusual barometers

There are many other more unusual types of barometer. From variations on the storm barometer, such as the Collins Patent Table Barometer, to more traditional-looking designs such as Hooke's Otheometer and the Ross Sympiesometer. Some, such as the Shark Oil barometer,[28] work only in a certain temperature range, achieved in warmer climates.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1509 2022-09-21 13:43:36

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1482) Euro

Summary

The euro (symbol: €; code: EUR) is the official currency of 19 out of the 27 member states of the European Union (EU). This group of states is known as the eurozone or, officially, the euro area, and includes about 340 million citizens as of 2019. The euro is divided into 100 cents.

The currency is also used officially by the institutions of the European Union, by four European microstates that are not EU members, the British Overseas Territory of Akrotiri and Dhekelia, as well as unilaterally by Montenegro and Kosovo. Outside Europe, a number of special territories of EU members also use the euro as their currency. Additionally, over 200 million people worldwide use currencies pegged to the euro.

As of 2013, the euro is the second-largest reserve currency as well as the second-most traded currency in the world after the United States dollar. As of December 2019, with more than €1.3 trillion in circulation, the euro has one of the highest combined values of banknotes and coins in circulation in the world.

The name euro was officially adopted on 16 December 1995 in Madrid. The euro was introduced to world financial markets as an accounting currency on 1 January 1999, replacing the former European Currency Unit (ECU) at a ratio of 1:1 (US$1.1743). Physical euro coins and banknotes entered into circulation on 1 January 2002, making it the day-to-day operating currency of its original members, and by March 2002 it had completely replaced the former currencies.

Between December 1999 and December 2002, the euro traded below the US dollar, but has since traded at or above the US dollar, peaking at US$1.60 on 18 July 2008 and since then returning near to its original issue rate. On 13 July 2022, the two currencies hit parity for the first time in nearly two decades due in part to the 2022 Russian invasion of Ukraine.

Details

Euro is the monetary unit and currency of the European Union (EU). It was introduced as a noncash monetary unit in 1999, and currency notes and coins appeared in participating countries on January 1, 2002. After February 28, 2002, the euro became the sole currency of 12 EU member states, and their national currencies ceased to be legal tender. Other states subsequently adopted the currency. The euro is represented by the symbol €.

The euro’s origins lay in the Maastricht Treaty (1991), an agreement among the then 12 member countries of the European Community (now the European Union)—United Kingdom, France, Germany, Italy, Ireland, Belgium, Denmark, the Netherlands, Spain, Portugal, Greece, and Luxembourg—that included the creation of an economic and monetary union (EMU). The treaty called for a common unit of exchange, the euro, and set strict criteria for conversion to the euro and participation in the EMU. These requirements included annual budget deficits not exceeding 3 percent of gross domestic product (GDP), public debt under 60 percent of GDP, exchange rate stability, inflation rates within 1.5 percent of the three lowest inflation rates in the EU, and long-term inflation rates within 2 percent. Although several states had public debt ratios exceeding 60 percent—the rates topped 120 percent in Italy and Belgium—the European Commission (the executive branch of the EU) recommended their entry into the EMU, citing the significant steps each country had taken to reduce its debt ratio.

Supporters of the euro argued that a single European currency would boost trade by eliminating foreign exchange fluctuations and reducing prices. Although there were concerns regarding a single currency, including worries about counterfeiting and loss of national sovereignty and national identity, 11 countries (Austria, Belgium, Finland, France, Germany, Ireland, Italy, Luxembourg, the Netherlands, Portugal, and Spain) formally joined the EMU in 1998. Britain and Sweden delayed joining, though some businesses in Britain decided to accept payment in euros. Voters in Denmark narrowly rejected the euro in a September 2000 referendum. Greece initially failed to meet the economic requirements but was admitted in January 2001 after overhauling its economy.

In 2007 Slovenia became the first former communist country to adopt the euro. Having demonstrated fiscal stability since joining the EU in 2004, both Malta and the Greek Cypriot sector of Cyprus adopted the euro in 2008. Other countries that adopted the currency include Slovakia (2009), Estonia (2011), Latvia (2014), and Lithuania (2015). (The euro is also the official currency in several areas outside the EU, including Andorra, Montenegro, Kosovo, and San Marino.) The 19 participating EU countries are known as the euro area, euroland, or the euro zone.

In 1998 the European Central Bank (ECB) was established to manage the new currency. Based in Frankfurt, Germany, the ECB is an independent and neutral body headed by an appointed president who is approved by all member countries to serve an eight-year term. The euro was launched on January 1, 1999, replacing the precursor ecu at a 1:1 value. Until the circulation of currency notes and coins in 2002, the euro was used only by financial markets and certain businesses. Many experts predicted that the euro could eventually rival the U.S. dollar as an international currency.

Unlike most of the national currencies that they replaced, euro banknotes do not display famous national figures. The seven colourful bills, designed by the Austrian artist Robert Kalina and ranging in denomination from €5 to €500, symbolize the unity of Europe and feature a map of Europe, the EU’s flag, and arches, bridges, gateways, and windows. The eight euro coins range in denominations from one cent to two euros. The coins feature one side with a common design; the reverse sides’ designs differ in each of the individual participating countries.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1510 2022-09-22 13:40:00

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,200

Re: Miscellany

1483) Dollar

Summary

A dollar is originally, a silver coin that circulated in many European countries; in modern times, the name of the standard monetary unit in the United States, Canada, Australia, New Zealand, and other countries. The Spanish peso, or piece of eight, which circulated in the Spanish and English colonies in America, was known as a dollar by the English-speaking peoples. Familiarity with this coin resulted in the official designation of the United States monetary unit as the dollar in 1792. Canada adopted the dollar and monetary decimal system in 1858; Australia in 1966; and New Zealand in 1967.