Math Is Fun Forum

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2025-05-05 21:11:26

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 53,341

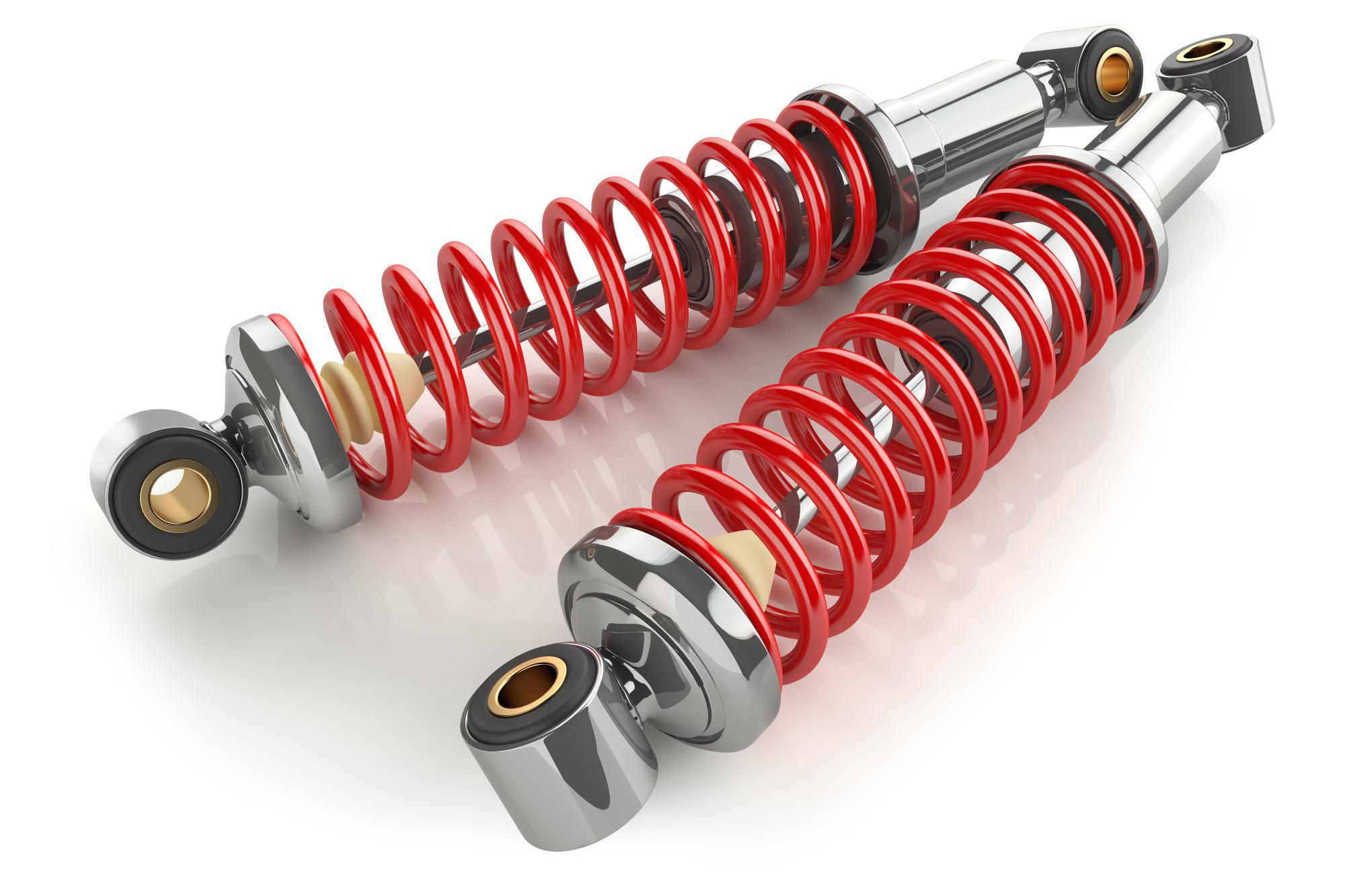

Shock absorber

Shock absorber

Gist

A shock absorber, also known as a damper, is a device that absorbs and dissipates shock impulses, primarily in vehicles, to provide a smoother ride and improve handling. It works by converting the kinetic energy of the shock into another form, typically heat, which is then dissipated.

Summary

A shock absorber is a device for controlling unwanted motion of a spring-mounted vehicle. On an automobile, for example, the springs act as a cushion between the axles and the body and reduce the shocks on the body produced by a rough road surface. Some combinations of road surface and car speed may result in excessive up-and-down motion of the car body. Shock absorbers slow down and reduce the magnitude of these vibratory motions. Modern shock absorbers are hydraulic devices that oppose both the compression and the stretch of the springs. The direct-acting, or strut, type is attached to the vehicle frame and the axle by two eyes. One eye is attached to a piston that slides in an oil-filled cylinder attached to the other eye. Any relative motion between the frame and the axle causes the piston to act against the oil in the cylinder. This oil has to leak through small openings or pass through a spring-loaded valve. In this way, a force is created that opposes the contraction and stretching of the springs, and the vibration of the body is dampened.

Details

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction).

Description

Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston.

One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be stored and used later. In general terms, shock absorbers help cushion vehicles on uneven roads and keep wheels in contact with the ground.

Vehicle suspension

In a vehicle, shock absorbers reduce the effect of traveling over rough ground, leading to improved ride quality and vehicle handling. While shock absorbers serve the purpose of limiting excessive suspension movement, their intended main purpose is to damp spring oscillations. Shock absorbers use valving of oil and gasses to absorb excess energy from the springs. Spring rates are chosen by the manufacturer based on the weight of the vehicle, loaded and unloaded. Some people use shocks to modify spring rates but this is not the correct use. Along with hysteresis in the tire itself, they damp the energy stored in the motion of the unsprung weight up and down. Effective wheel bounce damping may require tuning shocks to an optimal resistance.

Spring-based shock absorbers commonly use coil springs or leaf springs, though torsion bars are used in torsional shocks as well. Ideal springs alone, however, are not shock absorbers, as springs only store and do not dissipate or absorb energy. Vehicles typically employ both hydraulic shock absorbers and springs or torsion bars. In this combination, "shock absorber" refers specifically to the hydraulic piston that absorbs and dissipates vibration. Now, composite suspension systems are used mainly in 2 wheelers and also leaf springs are made up of composite material in 4 wheelers.

Construction

Shock absorbers are an important part of car suspension designed to increase comfort, stability and overall safety. The shock absorber, produced with precision and engineering skills, has many important features. The most common type is a hydraulic shock absorber, which usually includes a piston, a cylinder, and an oil-filled chamber. The piston is connected to the piston rod, which extends into the cylinder and divides the cylinder into two parts. One chamber is filled with hydraulic oil, while the other chamber contains compressed oil or air. When there is an accident or vibration in the vehicle, the piston moves into the cylinder, forcing the hydraulic fluid through small holes, creating resistance and dissipating energy in the form of heat. This dampens oscillations, reducing further bouncing or wobble of the car. Shock construction requires a balance of features such as piston design, fluid viscosity, and overall size of the unit to ensure performance. As technology developed, other types of shock absorbers emerged, including gas and electric shock absorbers, that provided improved control and flexibility. The design and manufacture of shock absorbers is constantly evolving due to the continuous improvement of vehicle dynamics and passenger comfort.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

Pages: 1