Math Is Fun Forum

You are not logged in.

- Topics: Active | Unanswered

#476 2019-08-14 00:11:46

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

389) Monkey

Monkey, in general, any of nearly 200 species of tailed primate, with the exception of lemurs, tarsiers, and lorises. The presence of a tail (even if only a tiny nub), along with their narrow-chested bodies and other features of the skeleton, distinguishes monkeys from apes. Most monkeys have a short, relatively flat face without great prominence of the muzzle, although baboons and mandrills are notable exceptions. The vast majority of species live in tropical forests, where they move on all four limbs. All but the durukuli of tropical Central and South America are active during the day, moving frequently in bands as they search for vegetation, birds’ eggs, smaller animals, and insects to eat. Monkeys are capable of sitting upright, and, consequently, their hands are freed for many manipulative tasks. Except for a few Old World forms, monkeys are predominantly arboreal, leaping from limb to limb in their travels among the trees. Their hands and feet are both used for grasping and typically have five digits, the thumb and big toe being divergent from the others. Commonly, the digits have flattened nails, but the marmosets have claws on all digits except the big toe, which bears a nail. On the ground, monkeys walk with the entire sole of the foot touching the ground but with the palm of the hand raised. They almost never walk on two legs (bipedally) and can stand erect for only short periods, if at all.

Monkeys have large brains and are known for their inquisitiveness and intelligence. Brain development, combined with the freeing of the hands and well-developed vision, allows them a great latitude of activity. Most are good at solving complex problems and learning from experience, but they do not quite reach the cognitive levels of great apes. Some, especially the capuchins (genus Cebus), spontaneously use objects as tools (e.g., stones to crack nuts). Others, such as baboons, readily learn to use sticks to obtain food. However, in strong contrast to the great apes (gorillas, chimpanzees, and orangutans), most monkeys do not appear to be very good at learning from each others’ experience—individuals more or less have to learn new behaviours for themselves. A significant exception is the Japanese macaque (Macaca fuscata). In field experiments, these monkeys were introduced to new foods such as sweet potatoes and candies wrapped in paper. Once a few individuals had solved the problems of getting at the new foods, their innovations gradually spread throughout entire troops. These experiments have had implications in redefining cultural behaviour.

Monkeys are highly social animals, and almost all live in troops consisting of several females with young and either a single male (as in hamadryas baboons, mandrills, most guenons, and most langurs) or several males (as in savannah baboons and macaques). Usually, but not universally, the females stay in the troop in which they were born and are thus closely related to each other. Males join new troops on maturity, and so they are unrelated to each other and somewhat antagonistic. Like humans and apes, female monkeys nurse their young and have a menstrual cycle, albeitless copious. In some species, physical activity is strictly confined to the period around ovulation (estrus); in others, there appears to be little or no restriction. Some species breed all year round; others have a period several months long during which they experience no cycles (anestrus).

Old World Monkeys Versus New World Monkeys

Monkeys are arranged into two main groups: Old World and New World. Old World monkeys all belong to one family, Cercopithecidae, which is related to apes and humans, and together they are classified as catarrhines(meaning “downward-nosed” in Latin). The New World monkeys are the platyrrhines (“flat-nosed”), a group comprising five families. As their taxonomic names suggest, New World (platyrrhine) and Old World (catarrhine) monkeys are distinguished by the form of the nose. New World monkeys have broad noses with a wide septum separating outwardly directed nostrils, whereas Old World monkeys have narrow noses with a thin septum and downward-facing nostrils, as do apes and humans. Old World monkeys have hard, bare “sitting pads” (ischial callosities) on the buttocks; New World monkeys lack these. Many Old World monkeys have thumbs that can be opposed to the other fingers and so can handle small objects precisely. None of the New World monkeys has such manual dexterity. Indeed, in the hands of many species, the main divergence is between the index and middle fingers; in a few species, the thumb is reduced or even absent. Some New World monkey species have prehensile tails capable of supporting the entire body weight or of grasping, for example, a proffered peanut. No Old World monkeys have this ability, and macaques are nearly tailless.

New World monkeys live primarily in tropical South America, especially the Amazon rainforests; the range of a few species extends northward as far as southern Mexico or southward into northern Argentina. Among the smaller New World forms that have endeared themselves to humans with their antics and their tamability are the alert marmosets, often tufted and colourfully arrayed, and the inquisitive squirrel, woolly, and capuchin monkeys—all of which exhibit in marked degree the curiosity and cleverness ascribed to monkeys generally. Larger New World species include the acrobatic spider monkeys and the noisy howlers. Other New World monkeys include uakaris, sakis, and titis.

Old World monkeys live throughout Africa, on the Red Sea coast of Arabia, and in Asia from Afghanistan to Japan and southeast to the islands of the Philippines, Celebes, Bacan, and Timor. Some Old World monkeys have been successfully naturalized in Gibraltar, France, Mauritius, Belau, and a few islands of the West Indies. Old World monkeys include many that are often seen in zoos, especially the beautifully coloured African guenons (e.g., mona, diana, white-nosed, green, vervet, and grivet monkeys), colobus, mangabeys, and the chiefly Asiatic macaques. The macaques include the Barbary “ape” of North Africa and the Rock of Gibraltar—the only macaque outside Asia and the only wild monkey inhabiting any part of Europe today—and the rhesus monkey of the Indian subcontinent, which has been used considerably in medical research. The graceful langurs include the hanuman, or sacred monkey, also of southern Asia. Among the more unusual monkeys are the large and strikingly coloured African drills and mandrills, the proboscis monkey of Borneo, and the rare and bizarre snub-nosed monkeys of China and Vietnam. The Old World monkeys are divided into two subfamilies: Cercopithecinae and Colobinae. The cercopithecines have cheek pouches, in which they store food; these include baboons, macaques, guenons, and their relatives. The colobines lack cheek pouches but have complicated three- or four-chambered stomachs, where bacterial fermentation of cellulose and hemicellulose occurs and thereby enriches the nutrient content of their diet, which consists partially of leaves and seeds. Colobines include colobus monkeys, langurs, and their relatives.

Because the ecological niches that they occupy are similar, there are many parallels between Old and New World monkeys. In particular, the squirrel monkeys (genus Saimiri) of the New World and the talapoin (genus Miopithecus) of West-Central Africa are remarkably convergent; both are small (about 1 kg [2.2 pounds]) and greenish, live in large troops along rivers, and breed seasonally. Other aspects of each group’s evolution, however, are unique. No New World monkey lives on the savanna or has a multichambered cellulose-fermenting stomach, and no Old World monkey is nocturnal like the durukuli. The closest analogue to the complex society of the spider monkey is found not in an Old World monkey but in the chimpanzee.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#477 2019-08-14 15:33:17

- Monox D. I-Fly

- Member

- From: Indonesia

- Registered: 2015-12-02

- Posts: 2,000

Re: Miscellany

Monkeys are capable of sitting upright, and, consequently, their hands are freed for many manipulative tasks.

Monkeys have large brains and are known for their inquisitiveness and intelligence. Brain development, combined with the freeing of the hands and well-developed vision, allows them a great latitude of activity. Most are good at solving complex problems and learning from experience, but they do not quite reach the cognitive levels of great apes. Some, especially the capuchins (genus Cebus), spontaneously use objects as tools (e.g., stones to crack nuts). Others, such as baboons, readily learn to use sticks to obtain food.

Monkeys in my countries are trained to steal tourists ' belongings in some vacation places. Not that I'm proud of it, though.

Actually I never watch Star Wars and not interested in it anyway, but I choose a Yoda card as my avatar in honor of our great friend bobbym who has passed away.

May his adventurous soul rest in peace at heaven.

Offline

#478 2019-08-16 00:34:10

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

390) Rubber

Think of rubber and you probably think of elastic bands, car tires, or pencil erasers. But this super-stretchy material actually finds its way into tens of thousands of different products—everything from rubber stamps and waterproof shoes to surfing wetsuits, swimming caps, and dishwasher hoses. Rubber, which has been commonly used for over 1000 years, once came entirely from natural sources; now rubber products are just as likely to be made artificially in chemical plants. That's largely because we can't produce enough natural rubber to meet all our needs. And that, in turn, is because rubber is so fantastically useful. Let's take a closer look at one of the world's most amazing materials!

What is rubber?

When people talk about "rubber", they don't usually specify what kind. There are many different kinds of rubber, but they all fall into two broad types: natural rubber (latex—grown from plants) and synthetic rubber (made artificially in a chemical plant or laboratory). Commercially, the most important synthetic rubbers are styrene butadiene (SBR), polyacrylics, and polyvinyl acetate (PVA); other kinds include polyvinyl chloride (PVC), polychloroprene (better known as neoprene), and various types of polyurethane. Although natural rubber and synthetic rubbers are similar in some ways, they're made by entirely different processes and chemically quite different.

Natural rubber

Natural rubber is made from a runny, milky white liquid called latex that oozes from certain plants when you cut into them. (Common dandelions, for example, produce latex; if you snap off their stems, you can see the latex dripping out from them. In theory, there's no reason why we couldn't make rubber by growing dandelions, though we'd need an awful lot of them.) Although there are something like 200 plants in the world that produce latex, over 99 percent of the world's natural rubber is made from the latex that comes from a tree species called Hevea brasiliensis, widely known as the rubber tree.

This latex is about one third water and one third rubber particles held in a form known as a colloidal suspension. Natural rubber is a polymer of isoprene (also known as 2-methylbuta-1,3-diene) with the chemical formula (C5H8)n. To put it more simply, it's made of many thousands of basic C5H8 units (the monomer of isoprene) loosely joined to make long, tangled chains. These chains of molecules can be pulled apart and untangled fairly easily, but they spring straight back together if you release them—and that's what makes rubber elastic.

Synthetic rubbers

Synthetic rubbers are made in chemical plants using petrochemicals as their starting point. One of the first (and still one of the best known) is neoprene (the brand name for polychloroprene), made by reacting together acetylene and hydrochloric acid. Emulsion styrene-butadiene rubber (E-SBR), another synthetic rubber, is widely used for making vehicle tires.

For the rest of this article, we'll concentrate mostly on natural rubber.

How is rubber made?

It takes several quite distinct steps to make a product out of natural rubber. First, you have to gather your latex from the rubber trees using a traditional process called rubber tapping. That involves making a wide, V-shaped cut in the tree's bark. As the latex drips out, it's collected in a cup. The latex from many trees is then filtered, washed, and reacted with acid to make the particles of rubber coagulate (stick together). The rubber made this way is pressed into slabs or sheets and then dried, ready for the next stages of production.

By itself, unprocessed rubber is not all that useful. It tends to be brittle when cold and smelly and sticky when it warms up. Further processes are used to turn it into a much more versatile material. The first one is known as mastication (a word we typically use to describe how animals chew food). Masticating machines "chew up" raw rubber using mechanical rollers and presses to make it softer, easier to work, and more sticky. After the rubber has been masticated, extra chemical ingredients are mixed in to improve its properties (for example, to make it more hardwearing). Next, the rubber is squashed into shape by rollers (a process called calendering) or squeezed through specially shaped holes to make hollow tubes (a process known as extrusion). Finally, the rubber is vulcanized (cooked): sulfur is added and the rubber is heated to about 140°C (280°F) in an autoclave (a kind of industrial pressure cooker).

Where does rubber come from?

As its name suggests, the rubber tree Hevea brasiliensis originally came from Brazil, from where it was introduced to such countries of the Far East as Malaysia, Indonesia, Burma, Cambodia, China, and Vietnam. During World War II, supplies of natural rubber from these nations were cut off just when there was a huge demand from the military—and that accelerated the development of synthetic rubbers, notably in Germany and the United States. Today, most natural rubber still comes from the Far East, while Russia and its former republics, France, Germany, and the United States are among the world's leading producers of synthetic rubber. The world's largest single source of latex rubber is the Harbel Rubber Plantation near Monrovia in Liberia, established in the 1920s and 1930s by the Firestone tire company.

Rubber—the kind you get from a tree—starts off as white and runny latex. Even when it's set into a product, this latex-based, natural rubber is very squashy, pretty smelly, and not very useful. The kind of rubber you see in the world around you, in things like car and bicycle tires, is vulcanized: cooked with sulfur (and often other additives) to make it harder, stronger, and longer lasting.

So what's the difference between raw, latex rubber and cooked, vulcanized rubber? In its natural state, the molecules in rubber are long chains that are tangled up and only weakly linked together. It's relatively easy to pull them apart—and that's why latex rubber is so stretchy and elastic. When latex is vulcanized, the added sulfur atoms help to form extra bonds between the rubber molecules, which are known as cross-links. These work a bit like the trusses you see on a bridge, tying the molecules together and making them much harder to pull apart.

What do we use rubber for?

The physical and chemical properties of a material dictate what we use it for. Even if you know absolutely nothing about the real-world uses of rubber, you can probably make some very good guesses. For example, everyone knows rubber is strong, stretchy, flexible (elastic), durable, and waterproof, so it's no surprise to find it used in things like waterproof clothes and wellington boots, sticking plasters, and adhesives.

The most important use of rubber is in vehicle tires; about half of all the world's rubber ends up wrapped around the wheels of cars, bicycles, and trucks! You'll find rubber in the hard, black vulcanized outsides of tires and (where they have them) in their inner tubes and liners. The inner parts of tires are usually made from a slightly different, very flexible butyl rubber, which is highly impermeable to gases (traps them very effectively), so tires (generally) stay inflated for long periods of time.

The fact that rubber can be made either soft or hard greatly increases the range of things we can use it for. Soft and stretchy latex is used in all kinds of everyday things, from pencil erasers, birthday balloons, and condoms to protective gloves, adhesives (such as sticky white PVA), and paints. Harder rubbers are needed for tougher applications like roofing membranes, waterproof butyl liners in garden ponds, and those rigid inflatable boats (RIBs) used by scuba divers. Because rubber is strong, flexible, and a very poor conductor of heat and electricity, it's often used as a strong, thin, jacketing material for electrical cables, fiber-optic cables, and heat pipes. But the range of applications is truly vast: you'll find it in everything from artificial hearts (in the rubber diaphragms that pump blood) to the waterproof gaskets that seal the doors on washing machines!

Neoprene (polychloroprene) is best known as the heat-insulating, outer covering of wetsuits—but it has far more applications than most people are aware of. Medical supports of various kind use it because, tightly fitted, it compresses and warms injured bits of your body, promoting faster healing. Since it's flexible and waterproof, it's also widely used as a building material, for example, as a roof and floor sealant, and as a spongy absorber of sound and vibration in door and window linings.

Although the world has a vast appetite for new rubber, we also produce a huge quantity of rubber waste, especially from discarded vehicle tires—and that's becoming an important raw material in its own right. According to the Rubber Manufacturers Association, the United States alone produced almost 270 million waste rubber vehicle tires in 2011, which is about a third of all the tires used worldwide. While some of these are retreaded and others are ground up to make a low-grade aggregate that can be used for the floors in things like children's playgrounds, over half of them are wasted (either burned as a fuel or buried in landfills). Rubber manufacturers have recently turned their attention to recycling tires in all kinds of new ways, making everything from mouse mats and sports bags to shoe soles and car components.

A brief history of rubber

*1000CE: Indians living in Central and South America have learned how to made waterproof clothes and shoes using latex from rubber trees. They call rubber trees "cahuchu" (crying wood), which is why the French still call rubber caoutchouc (pronounced "cow-chew") today.

*1731: During an expedition to South America, French explorer Charles Marie de La Condamine (1701–74) sends back samples of rubber to Europe, prompting intense scientific interest.

*1770: The discoverer of oxygen, English scientist Joseph Priestley (1733–1804), finds he can use pieces of rubber to erase the marks made by pencil on paper. In England, erasers are still widely called "rubbers" today.

*1791: Englishman Samuel Peal develops a method of waterproofing cloth with a rubber solution.

*1818: Scottish medical student James Syme (1799–1870) uses rubber-coated cloth to make raincoats.

*1823: Scotsman Charles Macintosh learns of Syme's discovery, refines it, and patents it, earning fame and fortune as the inventor of the rubberized, waterproof coat. Waterproof coats have been known as "Mackintoshes" (with a slight variation of spelling) ever since.

*1829: English chemist and physicist Michael Faraday (1791–1867) analyzes samples of Hevea and works out that the chemical formula for isoprene-type rubber is C5H8.

*1839: American inventor Charles Goodyear (1800–1860) accidentally discovers how to vulcanize rubber after dropping a piece of the material (which has been treated with sulfur) onto a hot stove.

*1830s~1840s: Botanist Thomas Lobb discovers a rubbery substance called Gutta-percha (Palaquium gutta) in Malaysia; Dr William Montgomerie, a surgeon working in the same region, sends samples back to Britain in 1843. According to a contemporary account by William Dalton, it has "remarkable properties, vast utility, and application to scientific and ornamental purposes" in everything from "boots and shoes" to "prevention of toothache."

*1876: Intrepid English explorer Sir Henry Wickham (1846–1928) smuggles thousands of seeds from the rubber tree Hevea brasiliensis out of Brazil and back to England. The English grow the seeds at Kew Gardens just outside London and export them to various Asian countries, establishing the giant plantations that now supply much of the world's rubber.

*1877: US rubber manufacturer Chapman Mitchell develops the first commercial process for recycling rubber from scratch.

*1882: John Boyd Dunlop (1840–1921) invents the pneumatic (air-filled) rubber tire. The development of gasoline-powered cars with rubber tires leads to a huge increase in the need for rubber.

*1883: US chemist George Oenslager (1873–1956) develops a much faster way of vulcanizing rubber using chemicals called organic (carbon-based) accelerators.

*1906–12: Bayer, a German chemical company, develops methyl rubber (a polymer of methylisoprene). It becomes critically important to Germany during World War I when supplies of natural rubber are cut off, but falls out of fashion when better alternatives are eventually developed.

*1910: English Chemist S.S. Pickles becomes the first person to propose (correctly) that rubber consists of long chains of isoprene. Technically, Hevea has the chemical name cis-1,4-polyisoprene, while Gutta-Percha is a variation known as trans-1,4-polyisoprene.

*1930: German chemical company IG Farben develops a type of general-purpose, synthetic rubber named Buna-S ("bu" from butadiene, "na" from the chemical symbol for sodium, and "S" for styrene). Technically, it's a copolymer of butadiene (75 percent) and styrene (25 percent), which is why it's now more generally known as styrene-butadiene or styrene-butadiene-rubber (SBR); it's also sold under tradenames such as Goodyear's Neolite®. Today, styrene-butadiene remains by far the world's most important synthetic rubber.

*1930: A team of US chemists at the DuPont company, led by Wallace Carothers (1896–1937), develop a revolutionary synthetic rubber called polychloroprene and sold as neoprene. (Shortly afterward, the same group developed an even more revolutionary material: nylon.)

*1940s: Synthetic rubbers are produced in the United States for the first time by companies such as Firestone, Goodyear, and Goodrich.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#479 2019-08-18 00:08:40

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

391) Firefly

Firefly, (family Lampyridae), also called lightning bug, any of some 2,000 species of beetles (insect order Coleoptera) found in most tropical and temperate regions that have special light-producing organs on the underside of the abdomen. Most fireflies are nocturnal, although some species are diurnal. They are soft-bodied beetles that range from 5 to 25 mm (up to 1 inch) in length. The flattened, dark brown or black body is often marked with orange or yellow.

Some adult fireflies do not eat, whereas many feed on pollen and nectar. In a few species females are predatory on males of other firefly species. Both sexes are usually winged and luminous, although in some species only one gender has the light-producing organ. Females lacking wings and resembling the long, flat larvae are commonly referred to as glowworms. The larvae are sometimes luminescent before they hatch. Larvae live on the ground and feed on snails and slugs by injecting a fluid into their prey and then withdrawing the partly digested matter through hollow mouthparts. The common glowworm (Lampyris noctiluca) is a member of this family.

Most fireflies produce short, rhythmic flashes in a pattern characteristic of the species. The rhythmic flash pattern is part of a signal system that brings the sexes together. Both the rate of flashing and the amount of time before the female’s response to the male are important. Some authorities feel that the flashing is also a protective mechanism, reminding predators of the firefly’s bitter taste. However, some frogs eat such large numbers of fireflies that they themselves glow.

Firefly light is produced under nervous control within special cells (photocytes) richly supplied with air tubes (tracheae). Firefly light is a cold light with approximately 100 percent of the energy given off as light and only a minute amount of heat. Only light in the visible spectrum is emitted. Some tropical members of the coleopteran family Elateridae are also called fireflies.

About Fireflies

Fireflies are familiar, but few realize that these insects are actually beetles, nocturnal members of the family Lampyridae. Most fireflies are winged, which distinguishes them from other luminescent insects of the same family, commonly known as glowworms.

Habitat

There are about 2,000 firefly species. These insects live in a variety of warm environments, as well as in more temperate regions, and are a familiar sight on summer evenings. Fireflies love moisture and often live in humid regions of Asia and the Americas. In drier areas, they are found around wet or damp areas that retain moisture.

Bioluminescence

Everyone knows how fireflies got their name, but many people don't know how the insects produce their signature glow. Fireflies have dedicated light organs that are located under their abdomens. The insects take in oxygen and, inside special cells, combine it with a substance called luciferin to produce light with almost no heat.

Firefly light is usually intermittent, and flashes in patterns that are unique to each species. Each blinking pattern is an optical signal that helps fireflies find potential mates. Scientists are not sure how the insects regulate this process to turn their lights on and off.

Firefly light may also serve as a defense mechanism that flashes a clear warning of the insect's unappetizing taste. The fact that even larvae are luminescent lends support to this theory.

Reproduction and Diet

Females deposit their eggs in the ground, which is where larvae develop to adulthood. Underground larvae feed on worms and slugs by injecting them with a numbing fluid.

Adults eschew such prey and typically feed on nectar or pollen, though some adults do not eat at all.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#480 2019-08-18 20:16:17

- Monox D. I-Fly

- Member

- From: Indonesia

- Registered: 2015-12-02

- Posts: 2,000

Re: Miscellany

The kind of rubber you see in the world around you, in things like car and bicycle tires, is vulcanized: cooked with sulfur (and often other additives) to make it harder, stronger, and longer lasting.

I remember when introducing One Piece to my classmate in High School, he was wondering "Why did Luffy's opponent get hurt being hit by Luffy whose body is rubber?" to which I immediately responded "Try getting thrown a tire at you. It hurts, doesn't it?".

Actually I never watch Star Wars and not interested in it anyway, but I choose a Yoda card as my avatar in honor of our great friend bobbym who has passed away.

May his adventurous soul rest in peace at heaven.

Offline

#481 2019-08-20 00:22:14

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

392) Milk

Milk, liquid secreted by the mammary glands of female mammals to nourish their young for a period beginning immediately after birth. The milk of domesticated animals is also an important food source for humans, either as a fresh fluid or processed into a number of dairy products such as butter and cheese.

Almost all the milk now consumed in Western countries is from the cow, and milk and milk products have become important articles of commerce. Other important sources of milk are the sheep and goat, which are especially important in southern Europe and the Mediterranean area; the water buffalo, which is widely domesticated in Asia; and the camel, which is important in the Middle East and North Africa.

Milk is essentially an emulsion of fat and protein in water, along with dissolved sugar (carbohydrate), minerals, and vitamins. These constituents are present in the milk of all mammals, though their proportions differ from one species to another and within species. The milk of each species seems to be a complete food for its own young for a considerable time after birth. In the stomachs of the young, milk is converted to a soft curd that encloses globules of fat, enabling digestion to proceed smoothly without the disturbance often caused by fatty food. Lactose, or milk sugar, is broken down into simpler digestible sugars by the enzyme lactase, which is produced in the intestine of infants. Infants who do not produce lactase develop lactose intolerance, a condition in which a variety of gastrointestinal problems arise. Lactose intolerance also commonly develops after weaning or with advancing age, when many individuals cease producing lactase.

Milk protein is of high nutritional value because it contains all the essential amino acids—i.e., those which infants cannot synthesize in the necessary quantities. Milk’s mineral content includes calcium and phosphorus in quantities sufficient for normal skeletal development, but little iron. Milk contains B vitamins as well as small amounts of vitamins C and D. Commercial cow’s milk is commonly enriched with vitamins D and A before sale.

Microorganisms contained in raw (unheated) milk or picked up from the environment will quickly sour and curdle the milk. Cooling to slightly above its freezing point keeps milk palatable for a longer time by reducing the multiplication of spoilage bacteria and the chemical changes that they induce.

Many countries have laws requiring that milk be pasteurized as a protection against pathogenic (disease-causing) organisms. Pasteurization is a partial sterilization accomplished by raising the milk to a temperature high enough to destroy pathogenic bacteria and a large proportion of those causing spoilage. Pasteurized milk that is kept refrigerated in closed containers will remain consumable for approximately 14 days.

Milk fat, being less dense than other milk components, can be efficiently removed in a cream separator by centrifugation, yielding low-fat milk and skim milk. Low-fat milk contains 1–2 percent fat, while skim milk contains less than 0.5 percent fat.

Much of the milk sold as a beverage has undergone homogenization, a process in which the milk is forced under high pressure through small openings to distribute the fat evenly throughout the milk.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#482 2019-08-20 14:55:14

- Monox D. I-Fly

- Member

- From: Indonesia

- Registered: 2015-12-02

- Posts: 2,000

Re: Miscellany

Most fireflies produce short, rhythmic flashes in a pattern characteristic of the species.

I remember when I and my friends were lost on a mountain forest at night 1 year ago. When my flashlight was the only one on and I tried to put it off, it was pitch-black darkness. We saw some flashing dots of light, and I asked my friends if those tiny hope spots might be humans. To my disappointment, they answered that no, they're just fireflies.

Actually I never watch Star Wars and not interested in it anyway, but I choose a Yoda card as my avatar in honor of our great friend bobbym who has passed away.

May his adventurous soul rest in peace at heaven.

Offline

#483 2019-08-20 15:30:25

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

Interesting!

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#484 2019-08-22 00:49:54

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

393) Honey

Honey, sweet, viscous liquid food, dark golden in colour, produced in the honey sacs of various bees from the nectar of flowers. Flavour and colour are determined by the flowers from which the nectar is gathered. Some of the most commercially desirable honeys are produced from clover by the domestic honeybee. The nectar is ripened into honey by inversion of the major portion of its sucrose sugar into the sugars levulose (fructose) and dextrose (glucose) and by the removal of excess moisture. Honey is stored in the beehive or nest in a honeycomb, a double layer of uniform hexagonal cells constructed of beeswax (secreted by the worker bees) and propolis (a plant resin collected by the workers). Honeycomb is used in winter as food for the larvae and other members of the colony. It is commonly sold by beekeepers as a delicacy, or the wax may be extracted for various purposes.

Honey contains about 18 percent water, is water soluble, and may granulate between 50 and 65 °F (10 and 18 °C). Somewhat acid, it has mild antiseptic properties and has been used in the treatment of burns and lacerations. One of the most easily assimilated foods, it is widely used in baked goods, candies, prepared fruits, cereals, and medicines.

Honey was almost the only source of sugar available to the ancients and was valued for its medicinal benefits. It was used to make mead, a fermented beverage, and was mixed with wine and other alcoholic drinks. In Egypt it was employed as an embalming material. In India and other Asian countries it was used to preserve fruit and make cakes, sweetmeats, and other foods. Honey is mentioned in the Bible and in the Qurʾān.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#485 2019-08-24 00:26:31

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

394) Yam

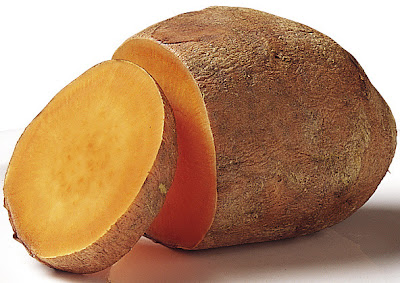

Yam, any of several plant species of the genus Dioscorea (family Dioscoreaceae) grown for their edible tubers. Yams are native to warmer regions of both hemispheres, and several species are cultivated as staple food crops in the tropics. In certain tropical cultures, notably in West Africaand New Guinea, the yam is the primary agricultural commodity and the focal point of elaborate rituals.Yams are consumed as cooked starchy vegetables. They are often boiled and then mashed into a sticky paste or dough, but they may also be fried, roasted, or baked in the manner of potatoes.

True yams are botanically distinct from the unrelated sweet potato (Ipomoea batatas), but moist-fleshed varieties of sweet potato are often called yams in the United States. The air-potato yam (D. bulbifera) is one of the few true yams cultivated for food in the United States.

Yam plants have thick tubers (generally a development of the base of the stem), from which protrude long, slender, annual, climbing stems. The leaves are either alternate or opposite and can be entire or lobed. The unisexual flowers are borne in long clusters. The flowers are generally small and individually inconspicuous though collectively showy. Each consists of a greenish bell-shaped or flat perianth of six pieces, enclosing six or fewer stamens in the male flowers and surmounting a three-celled three-winged ovary in the female flowers. The ovary ripens into a membranous capsule, bursting by three valves to liberate numerous flattish or globose seeds.

Yam flesh ranges in colour from white to yellow, pink, or purple and varies in taste from sweet to bitter to tasteless. Most yams contain an acrid principle that is dissipated in cooking. Indian yam (D. trifida) and winged, or water, yam (D. alata) are the edible species most widely diffused in tropical and subtropical countries. The tubers of D. alata sometimes weigh 45 kg (100 pounds). Guinea yam (D. rotundata) and yellow Guinea yam (D. cayenensis) are the main yam species grown in West Africa. Lesser yam (D. esculenta), grown on the subcontinent of India, in southern Vietnam, and on South Pacific islands, is one of the tastiest yams. Chinese yam (D. polystachya), also known as cinnamon vine, is widely cultivated in East Asia.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#486 2019-08-26 00:49:08

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

395) Frogs

Facts About Frogs & Toads

Frogs are amphibians that are known for their jumping abilities, croaking sounds, bulging eyes and slimy skin. They live all over the world and are among the most diverse animals in the world, with more than 6,000 species.

Frogs substantially outnumber the two other groups of amphibians — salamanders and caecilians. According to the American Museum of Natural History (AMNH) online reference site, Amphibian Species of the World, which is updated in real time, as of late April 2015, there are 6,482 species in the Anura order (frogs and toads), 691 species in the Caudata order (salamanders and newts) and 204 species in the Gymnophiona order (caecilians). Caecilians look like large worms or slick snakes, according to the San Diego Zoo. They have no arms or legs, and live underground in a network of tunnels.

Frogs vs. toads

There is no scientific distinction between frogs and toads, according to the University of Michigan Museum of Zoology. Frog and toads both belong to the Anura order, but are found in different families. "True toads" make up the Bufonidae family, which includes 580 species.

Frogs and toads do have specific traits that define them, however, according to the Maryland Zoo. For example, frogs are mostly aquatic; most toads live on land (but near water). Frogs have teeth; toads do not. Toads of both male and female have a rudimentary ovary called a bidder's organ. Frogs are also typically longer than toads.

Also, frogs have smooth, slimy skin; toads have dry, bumpy skin. The bumps, however, are not warts, and a person cannot get warts from handling a toad, according to the San Diego Zoo. However, toads have glands behind their eyes that can secrete a burning milky toxin.

Size & appearance

Some frogs have toxic skin. Some South American frogs are so toxic that one drop of their skin secretions can kill an adult human. Poison frogs usually have bright colors to warn predators that their skin is toxic, according to the San Diego Zoo. Camouflage is another survival technique. Many frogs have mottled green or brown skin to help them blend in with their surroundings.

Since there are so many types of frogs, one size doesn't fit all. The largest frog is the Goliath frog, which is 13.5 inches long (30 centimeters) and weighs 6.6 lbs. (3 kilograms), according to the San Diego Zoo. The devil frog of Madagascar, now extinct, once held the title of largest frog. It was 16 inches long (41 cm) long and weighed 10 lbs. (4.5 kg), according to National Geographic.

The smallest frog is the gold frog, which is a tiny 0.39 in (1 cm) long and only 7 ounces (200 grams), according to the San Diego Zoo. That's around the size of a dime.

Habitat

Frogs need to be around areas with a water source to reproduce, but other than that, they are found on every continent except Antarctica and in almost every environment. The poison dart frog lives in the tropical forests of Central and South America. Northern leopard frogs live in the northern areas of North America in marshes and grasslands. The green-eyed tree frog lives in the moss-covered rain forests of Queensland, Australia, according to National Geographic. The desert rain frog lives exclusively in Namibia and South Africa, along the coast in sand dunes.

Diet

Frogs will often eat any living thing that will fit into their mouths. This includes bugs, spiders, worms, slugs, larvae and even small fish. To catch prey, their sticky tongues will dart from their mouths and pull the prey into the frog's mouth. This movement is so fast often the prey doesn't have a chance to escape. A frog's tongue can snap back into its mouth within 15/100ths of a second.

Frogs and toads help keep the world's insect population under control, according to the San Diego Zoo. Their appetite for bugs is usually quite helpful, but sometimes it can lead to disaster. For example, in 1935, cane toads from Puerto Rico were introduced to Australia to kill sugarcane beetles. However, the cane toads, which can grow as large as a dinner plate, preferred to eat native frogs, small marsupials and snakes. The original 102 toads set out across the continent and have mushroomed in number to more than 1.5 billion, according to a 2010 Live Science article. Today, cane toads have conquered more than 386,000 square miles (1 million square kilometers) of Australia. This is equivalent to an area slightly larger than the states of Texas and Oklahoma combined.

Habits

Frogs are social creatures that live in groups. A group of frogs is called army, colony or a knot. Groups of young frogs will even swim together in schools, much like fish.

During mating season, the male frogs in a group will croak quite loudly. Frogs croak to attract females. When the female finds a male croak she likes, the male will grab her and she will release eggs for him to fertilize.

Offspring

Frogs become mature between two months to 3 years old. Colder temperatures can determine how fast a frog matures, as well as the species of frog. After a female frog becomes mature, she can lay from two to more than 50,000 eggs at once, depending of species. Eggs will incubate for 48 hours to 23 days, submerged in water, according to the San Diego Zoo. During incubation, the male frog typically protects the eggs.

Once an egg hatches, a small, legless, fish-like creature emerges. This frog offspring is called a tadpole. The change from a tadpole to a frog is started by hormones from the tadpole's thyroid gland according to the National Center for Biotechnology Information. Over time, the tadpole will grow legs, lose its tail and will emerge from the water onto land. How fast the tadpole transforms depends on environmental factors.

Classification/taxonomy

The taxonomy of frogs, according to the AMNH, is:

• Kingdom: Animalia

• Subkingdom: Bilateria

• Infrakingdom: Deuterostomia

• Phylum: Chordata

• Subphylum: Vertebrata

• Infraphylum: Gnathostomata

• Superclass: Tetrapoda

• Class: Amphibia

• Order: Anura

• Family, Genus & Species: There are 54 families, comprising more than 300 genera and 6,481 species.

Conservation status

While some frogs are safe and prolific, others are endangered, according to the International Union for Conservation of Nature (IUCN). The group's Red List of Threatened Species lists the lemur leaf frog, black-eyed leaf frog and Vanzolini's spiny-chest frog as critically endangered.

Other facts

The word "amphibian" comes from a Greek word that means "both lives." This is because frogs start their lives in the water and then live on land, according to Defenders of Wildlife.

All frogs are known for their fantastic jumping skills, but the African frog is the best. It can jump 14 feet (4.2 meters) in a single bound, according to the San Diego Zoo.

Not all frogs hop, though. The waxy tree frog walks like a lizard.

Amazon horned frogs are ambush predators and aggressively territorial. Some Amazon villagers wear high leather boots to repel attacks, according to National Geographic.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#487 2019-08-26 15:39:21

- Monox D. I-Fly

- Member

- From: Indonesia

- Registered: 2015-12-02

- Posts: 2,000

Re: Miscellany

Frogs have teeth; toads do not.

Why did I never realize this, even though I saw them when eating some fried frogs.

Actually I never watch Star Wars and not interested in it anyway, but I choose a Yoda card as my avatar in honor of our great friend bobbym who has passed away.

May his adventurous soul rest in peace at heaven.

Offline

#488 2019-08-28 01:05:20

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

396) Volcano

Volcano Facts and Types of Volcanoes

A volcano on Earth is a vent or fissure in the planet's crust through which lava, ash, rock and gases erupt. A volcano is also a mountain formed by the accumulation of these eruptive products.

Volcanoes have existed for a long time on Earth, likely causing disasters such as the Permian mass extinction about 250 million years ago, the greatest mass extinction in Earth's history, according to a 2015 paper. Volcanoes can and have existed on other worlds as well: although volcanoes on the moon and Mars have long been dormant, volcanoes are still very active on Jupiter's moon Io. Researchers are currently striving to find ways to predict when volcanic eruptions might happen on Earth by analyzing clues such as crystals and gases linked with volcanoes.

Let's take a look at how volcanoes form on Earth:

Earth's crust is 3 to 37 miles (5 to 60 kilometers) thick, according to the U.S. Geological Survey. It is broken up into seven major and 152 smaller pieces called tectonic plates, according to a 2016 paper by Christopher Harrison at the University of Miami. These plates float on a layer of magma — semi-liquid rock and dissolved gases. At the boundaries of these plates — where they move past, are pushed under, or move away from each other — magma, which is lighter than the surrounding solid rock, is often able to force its way up through cracks and fissures. Magma can explode from the vent, or it can flow out of the volcano like an overflowing cup. Magma that has erupted is called lava.

Principal types of volcanoes

Cinder cone volcanoes (also called scoria cones) are the most common type of volcano, according to San Diego State University, and are the symmetrical cone-shaped volcanoes we typically think of. They may occur as single volcanoes or as secondary volcanoes known as "parasitic cones" on the sides of stratovolcanoes or shield volcanoes. Airborne fragments of lava, called tephra, are ejected from a single vent. The lava cools rapidly and fall as cinders that build up around the vent, forming a crater at the summit, according to the U.S. Geological Survey. Cinder cone volcanoes are fairly small, generally only about 300 feet (91 meters) tall and not rising more than 1,200 feet (366 meters). They can build up over short periods of a few months or years.

Stratovolcanoes are also called composite volcanoes because they are built of layers of alternating lava flow, ash and blocks of unmelted stone, according to the U.S. Geological Survey. They are larger than cinder cones, rising up to 8,000 feet (2,438 meters). Stratovolcanoes result from a conduit system of vents leading from a magma reservoir beneath the surface. When dormant, they typically have steep concave sides that sweep together at the top around a relatively small crater.

Stratovolcanoes can erupt with great violence. Pressure builds in the magma chamber as gases, under immense heat and pressure, are dissolved in the liquid rock. When the magma reaches the conduits the pressure is released and the gases explode, like soda spewing out of a soda can that you shook up and opened suddenly, according to San Diego State University. Because they form in a system of underground conduits, stratovolcanoes may blow out the sides of the cone as well as the summit crater.

Stratovolcanoes are considered the most violent. Mount St. Helens, in Washington state, is a stratovolcano that erupted on May 18, 1980. Approximately 230 square miles (596 square kilometers) of forest was completely obliterated and 57 people were killed. Over the course of the day, winds blew 520 million tons of ash eastward across the United States and caused complete darkness in Spokane, Washington, 250 miles (402 kilometers) from the volcano, according to the U.S. Geological Survey.

Shield volcanoes are huge, gently sloping volcanoes built of very thin lava spreading out in all directions from a central vent. They have wide bases several miles in diameter with steeper middle slopes and a flatter summit. The gentle convex slopes give them an outline like a medieval knight’s shield. Eruptions of these volcanoes are not generally explosive, but are more like liquid overflowing around the edges of a container. The world's largest volcano, Mauna Loa in Hawaii, is a shield volcano, according to the U.S. Geological Survey. Mauna Loa is about 55,770 feet (17,000 meters) from its base beneath the ocean to the summit, which is 13,681 feet (4,170 meters) above sea level. It is also one of the Earth's most active volcanoes and is carefully monitored. The most recent eruption was in 1984.

Lava domes are built up when the lava is too viscous to flow, according to the U.S. Geological Survey. A bubble or plug of cooling rock forms over a fissure. This cooler, thick lava usually rises near the end of an explosive eruption and lava domes often form within the craters of stratovolcanoes. Mount St. Helens has several well-defined lava domes inside the crater, according to NASA.

Other volcanic landforms

Besides well-known symmetrical volcanoes such as Mount Fuji in Japan and Kilimanjaro in Tanzania, volcanic activity is responsible for several other distinctive landforms.

Calderas: A caldera is a bowl-shaped depression formed when a volcano collapses into the void left when its magma chamber is emptied. There are three types, according to San Diego State University. The first type is a crater lake caldera. This is the result of a stratovolcano collapsing into its magma chamber during a violent eruption. Basaltic calderas have a concentric ring pattern resulting from a series of gradual collapses rather than a single event. They are often found at the summit of shield volcanoes such as the craters at the tops of Mauna Loa and Kilauea. Resurgent calderas are the largest volcanic structures on Earth. They are the result of catastrophic eruptions that dwarf any eruptions ever recorded by human beings. Yellowstone caldera, sometimes called a "super volcano," is one example.

Volcanic plugs: When magma solidifies in the fissure of a volcano the hard dense rock may form a "neck" that remains when softer surrounding rock has been eroded away, according to the U.S. Geological Survey. This can result in dramatic landmarks such as Ship Rock in New Mexico, and Devil's Tower in Wyoming.

Tuff cones: also known as maars, tuff cones are shallow, flat-floored craters that scientists think formed as a result of a violent expansion of magmatic gas or steam, according to the U.S. Geological Survey. Maars range in size from 200 to 6,500 feet (60 to 1,980 meters) across and from 30 to 650 feet (9 to 198 meters) deep, and most are commonly filled with water to form natural lakes. Maars occur geologically young volcanic regions of the world such as the western United States and the Eifel region of Germany.

Lava plateaus: Shield volcanoes may erupt along lines of fissures rather than a central vent spilling liquid lava in successive layers. Over time as these layers form broad plateaus such as the Columbia Plateau, according to the Encyclopedia Britannica. These plateaus are often cut by deep canyons that expose the layers of rock.

Volcanoes in history

A.D. 79: One of the most famous volcanoes is Mount Vesuvius, which sits along the Bay of Naples in southern Italy. It has erupted dozens of times in the past 2,000 years, according to the Encyclopedia Britannica. The A.D. 79 eruption, which buried Pompeii, made Vesuvius famous, but another eruption in 1631 killed about 3,000 people.

1669: In Sicily, Mount Etna sent a river of lava flooding through Catania, according to Geology.com, killing some 20,000 people there and in the surrounding region, according to NASA. [Video: Mount Etna's Dramatic New Eruption]

1783: The eruption of Mount Skaptar in Iceland devastated farming and fishing, causing a famine that killed a quarter of the country's people, according to Oregon State University.

1815: Whirlwinds and tsunamis from the eruption of Mount Tambora, on Sumbawa Island in Indonesia, killed at least 10,000 people, according to the Encylopedia Britannica. The volcano sent a cloud ejecta into the atmosphere that was more than four times the amount ejected by Mount Pinatubo in 1991, leading to the "Year Without a Summer" of 1816 in Europe and North America, according to a 2016 paper in Wiley Interdisciplinary Reviews: Climate Change.

1883: Another Indonesian volcano, Krakatoa, erupted in an explosion heard 3,000 miles away. Seventy-pound boulders landed on islands 50 miles away, and a 130-foot tsunami devastated hundreds of villages, including Java and Sumatra, according to San Diego State University. About 36,000 people died. Dust high in the atmosphere caused the moon to appear blue, and sometimes green, for two years, according to NASA.

1902: Mount Pelée, on the island of Martinique, smothered the town of Saint-Pierre in deadly gas and hot ash, killing 29,933, according to the Los Angeles Times.

1980: Mount St. Helens in Washington state blew 1,300 feet off its top, killing 57 people and causing a midday darkness in towns 85 miles away.

1991: After 600 years of dormancy, Mount Pinatubo in the Philippines rumbled for days before erupting and killing more than 840 people, according to the U.S. Geological Survey. The cataclysmic ejected more than 1 cubic mile (5 cubic kilometers) of material and buried a U.S. air base 15 miles away, according to the National Oceanic and Atmospheric Administration. Nearly every bridge within 18 miles (30 km) of Mount Pinatubo was destroyed, according to the U.S. Geological Survey.

Pinatubo's cloud of sulfuric acid, some 20 million tons of it, climbed to more than 12 miles in the stratosphere. Over the next several weeks, the cloud encircled the equator and spread to the poles, covering the entire planet. The particles reflected sunlight and cooled the Earth by nearly a full degree Fahrenheit.

Other significant U.S. volcanoes

Lassen Peak, California: Erupted between 1914 and 1917, causing no deaths, according to the National Park Service. Lassen is considered one of the most likely in the Cascade Range to erupt again.

Long Valley, California: The Long Valley Caldera is a 10-by 20-mile (16-by-32 kilometer) depression in the Sierra Nevada Mountains caused by an eruption 700,000 years ago, according to the U.S. Geological Survey. A tremendous explosion spit out molten rock from 4 miles under the surface; afterward, the whole mess settled more than a mile down into the depression where the magma had been.

Magma still feeds hot springs in the caldera. Earthquakes in 1980 marked the beginning of new activity that has included shifts in the position of hot springs and swarms of other small earthquakes. Geologists say it probably indicates that magma is again rising from below, and they suspect the area will erupt again.

Mount Shasta, California: Last known eruption was in 1786. It is believed to erupt every 600 to 800 years, according to the U.S. Geological Survey. The mountain is significant as the incredibly dominant visual element in the Northern California landscape.

Kilauea and Mauna Loa, Hawaii: Each tends to erupt every two or three years; eruptions are non-explosive, allowing these two volcanoes to be among the most studied active volcanoes in the world, according to the U.S. Geological Survey and the University of Hawaii.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#489 2019-08-30 00:22:42

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

397) Ferris Wheel

Background

A ferris wheel is an amusement park ride consisting of a large vertical wheel with places for people to sit or stand spaced evenly around the outer circumference. In operation, the ferris wheel revolves about a horizontal axis, and the riders are alternately lifted and then lowered as they are carried around the wheel in a circle. When the wheel stops, the people in the seat or platform at ground level exit the ride, and new riders take their place. The wheel then revolves a short distance until the next seat or platform is at ground level, allowing more people to exit and enter. This procedure is repeated until all the seats or platforms are filled with new riders, at which time the wheel is set in motion to undergo several complete revolutions. Although the name "ferris wheel" was not used until the 1890s, the wheel itself has been a part of human festivities for hundreds of years.

History

The earliest designs of wheels used for amusement rides may have been based on the large, circular wheels used to lift water for irrigation. In fact, knowing the human spirit, it is probable that adventuresome children used these water wheels for entertainment from the time they were first developed in about 200 b.c.

English traveler Peter Mundy described what he called a "pleasure wheel" with swings for seats after he visited a street fair in Turkey in 1620. In England, small hand turned wheels were called "ups-and-downs" as early as 1728.

Whatever they were called, amusement wheels found their way to many parts of the world. One of the first wheels in the United States was built in 1848 by Antonio Maguino, who used it to draw crowds to his rural park and picnic grounds in Walton Spring, Georgia. As the concept of mixing amusement rides with park and picnic facilities caught on, several companies began manufacturing wheels of various designs. In 1870, Charles W.P. Dare of Brooklyn made several wood wheels of 20-and 30-ft (6.1-and 9.1-m) diameters, which he sold as the Dare Aerial Swing. The Conderman Brothers of Indiana made an even larger wheel when they developed a 35-ft (10.7-m) metal wheel in the 1880s.

The race for larger wheels culminated in early 1893 when American bridge builder and engineer, George Washington Gale Ferris, began building a 250-ft (76.2-m) wheel for the 1893 Colombian Exposition in Chicago. Designed like a bicycle wheel, with a stiff steel outer rim hung from the center axle by steel spokes under tension, the wheel could carry as many as 1,440 passengers at a time in 36 enclosed cars. The center axle was 33 in (84 cm) in diameter and 45.5 f (13.9 m) in length. It weighed 46.5 tons (42.2 metric tons) and was the largest steel forging ever produced at the time. The giant wheel opened on June 21, 1893, and drew more than 1.4 million paying customers during the 19 weeks it was in operation. The overwhelming success of Ferris' design ensured that his name would be forever linked with such wheels.

One of the people who rode the ferris wheel at the Colombian Exposition was American inventor and bridge builder William E. Sullivan. Sullivan was fascinated with the wheel and rode it many times. What was especially attractive to him was the possibility of making a smaller wheel that could be taken down and moved from one park or fairground to another. Drawing on his experience with bridges, he designed a 45-ft (13.7-m) transportable wheel with twelve three-passenger seats in 1900. In 1906 he formed the Eli Bridge Company and started manufacturing his wheel in Roodhouse, Illinois. Later he moved the company to Jacksonville, Illinois, where it remains in operation today. Most of the ferris wheels found in carnivals and fairs in the United States are made by the Eli Bridge Company.

Raw Materials

Because of the unique design of a ferris wheel, most of the component parts are fabricated by the manufacturer. Steel is the most common raw material and is used to make the trailer chassis, wheel support towers, wheel spokes, and wheel crossmembers. A variety of structural steel shapes are used depending on the application. They include square tubing, round tubing, angles, channels, and wide-flanged beams. Aluminum diamond tread plate is used for the entrance and exit walk-ways and for the operator's platform.

Aluminum is used to make the seats and the drive rims. The drive rims are rolled out of aluminum angle stock and are attached to the spokes to form a large circle about 10 ft (3 m) smaller in diameter than the outer rim of the wheel itself. Two rubber drive wheels press against the drive rims on each side to rotate the wheel. Aluminum is used in this application because the constant rubbing of the drive wheels quickly removes the paint on the rims, exposing the bare metal. If steel were used, it would rust.

The cushions used on the seats are molded from a self-skinning polyurethane foam. This material forms a solid, smooth skin on the outside, while the inside remains a compressible foam. Nylon is used for some of the bushings, and a phenolic plastic is used in some of the electrical components. Support cables within the wheel structure may have a plastic cover for appearance and protection from the elements. The electrical rings that carry electrical power from the hubs to the lights along the rotating spokes are made of copper, and the brushes that bring the power to the rings are made of carbon.

Some ferris wheel components are purchased from other manufacturers and are installed on the ferris wheel when it is built. These include the axles, brakes, tires, and wheels on the trailer. Other purchased components include the electric drive motors, the electrical wires and cables, and the electrical light bulbs and sockets.

Design

Ferris wheels that are designed to be transported on the road from one location to another must conform to the overall width, height, and length restrictions for highway vehicles. Although these restrictions vary from state to state, most states limit the trailer width to 8.5 ft (2.6 m), the height to 13.5 ft (4.1 m), and the length to 55 ft (16.8 m). No matter how big or small the ferris wheel is when it is opened and in operation, it must fold down to meet these restrictions when it is travelling on the highway.

The ferris wheel must also be designed to operate safely. This requires calculations to ensure the horizontal and vertical forces of the fully loaded wheel can be supported when the wheel is in operation. It also requires the design of safety interlocks to prevent the wheel from revolving during loading and unloading operations, and to prevent the operator from inadvertently operating the wheel in an unsafe manner.

The Manufacturing Process

The manufacturing processes used to make ferris wheels varies with the design of the wheel and the manufacturer. Most of the components are built in different parts of the shop before they are brought to the main construction area for final assembly. Here is a typical sequence of operations used to build a transportable ferris wheel used in carnivals and county fairs. In operation, the wheel described is about 60 ft (18.3 m) in diameter with a capacity to carry up to 48 riders in 16 seats.

Building the chassis

• 1. The trailer chassis forms the base for the ferris wheel, both when it is being transported on the highway and when it is in operation. The component parts of the chassis are cut to length, either with a metal-cutting saw or with a torch, and are welded together. Two vertical support posts are welded to the forward section of the chassis. These posts hold the upper end of the two wheel support towers when they are in their lowered position for travelling.

• 2. The completed chassis is then sandblasted to remove any scale and spatter formed during the welding operation. This ensures a smooth surface appearance and prevents the scale from chipping off later and leaving patches of bare steel.

• 3. The chassis is then coated with a rust-in-hibiting primer. After the primer has dried, one or more coats of finish paint are applied in the desired color.

Installing the towers

• 4. The two wheel support towers are fabricated and painted elsewhere and are lifted into position on the chassis. The lower ends are attached to hinges on each side of the chassis, and the upper ends rest on the two support posts. The towers include ladders welded along one edge to provide access to the electrical rings and brushes at the wheel hubs and to the electrical drive motors and wheels that tum the drive rim on each side. The center axle is then installed between the wheel hubs at the tops of the two towers.

• 5. A long hydraulic cylinder is attached between the chassis and the wheel support tower on each side, about halfway along the length of the tower. These hydraulic cylinders are used to raise the towers into their upright position when the ferris wheel is being set up for operation. The cylinders are secured in place with a pivot pin at each end.

• 6. A separate lateral support arm is attached near the top of each wheel support tower. These arms each consist of two pieces of square tubing, with one piece slightly smaller in cross section so it slides inside the other. When the wheel support towers are raised for operation, the lateral support arms are pulled out to the side and the inner section of each is extended and locked in place with a pin. Two other pieces of square tubing are hinged to the chassis frame on each side and swing out to attach to the bases of the lateral supports. This gives the ferris wheel the required side-to-side stability it needs.

• 7. Hydraulic and electrical lines are routed inside the chassis frame pieces where they will be protected. The operator's control station is installed and connected. The chassis axles, brakes, tires, wheels, and stabilizer jacks may be installed at this time or they may be installed after all other work is complete.

Installing the spokes

• 8. Sixteen pairs of spokes run from the center hubs at the tops of the towers out to the seats. To install the spokes in the factory, the first pair of spokes is laid flat on the factory floor, and two crossmembers are installed between the spokes. One crossmember is located at the point where the drive rims will be attached, which is about 5 ft (1.5 m) in from the outer end of the spokes. A pair of curved sections of the drive rims are also bolted in place on each side at the same point. Only one end of the drive rim sections are bolted, leaving the other end free. This procedure is repeated for the remaining spokes, crossmembers, and drive rim sections until they form a stack. The inner ends of each pair of spokes are pinned to the pair below it. V-shaped lighting booms are installed between the center of every other outer crossmember as the stack is assembled. This overlapping pattern of lights produces a double-star effect.

• 9. The stack is then lifted onto the trailer with an overhead crane, and the top pair of spokes is pinned to the hubs. In operation, the spokes are all pulled into the vertical position when the towers are raised. The spokes are then pinned to the hubs, one pair at a time, and the free ends of the drive rim sections are swung down and bolted to the adjacent spokes to form the wheel—like a paper fan being unfolded.

• 10. Electrical cables are connected from the electrical rings at the wheel hubs to each lighting boom. Mechanical support cables are installed between the ends of the spokes around the outer circumference of the wheel. Other mechanical cables are installed in an x-pattern between each pair of spokes to give additional stability.

Finishing the wheel

• 11. The entrance and exit stairs and walkways, safety fences, and trim pieces are fabricated, painted, and installed. The seats are fabricated and painted. In operation, four of the seats are carried attached to the wheel. The remaining seats are carried separately on the trailer and are manually lifted and pinned into place after the wheel is erected.

Safety Considerations

As with any amusement park ride, safety is the primary concern of both the manufacturer and the operator. Current safety regulations governing ferris wheels vary from city to city and state to state. The American Society for Testing and Materials (ASTM) is in the process of developing a comprehensive standard for the design, testing, manufacturing, and operation of all amusement park rides. Ferris wheel manufacturers and amusement park operators are actively participating in this process.

The Future

Having provided entertainment for several hundred years, if not several thousand years, the ferris wheel will probably continue to be a pleasurable experience for many years to come. Although roller coasters and other thrill rides may dominate amusement parks, the ferris wheel will still give riders the gentle thrill of being carried up in the air in an open seat to hang high above the crowds on a warm summer evening.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#490 2019-09-01 01:18:31

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

398) Rainbow

Rainbow, series of concentric coloured arcs that may be seen when light from a distant source—most commonly the Sun—falls upon a collection of water drops—as in rain, spray, or fog. The rainbow is observed in the direction opposite to the Sun.

The coloured rays of the rainbow are caused by the refraction and internal reflection of light rays that enter the raindrop, each colour being bent through a slightly different angle. Hence, the composite colours of the incident light will be separated upon emerging from the drop. The most brilliant and most common rainbow is the so-called primary bow, which results from light that emerges from the drop after one internal reflection.

Although light rays may exit the drop in more than one direction, a high density of the rays emerge at a minimum angle of deviation from the direction of the incoming rays. The observer thus sees the highest intensity looking at the rays that have minimum deviation, which form a cone with the vertex in the observer’s eye and with the axis passing through the Sun. Light emerging from raindrops after one internal reflection has a minimum deviation of about 138° and thus the greatest intensity in the directions forming a cone with an angular radius of about 42°, with arcs (from inside to outside) of violet, indigo, blue, green, yellow, orange, and red.

Occasionally, a secondary bow may be observed, which is considerably less intense than the primary bow and has its colour sequence reversed. The secondary rainbow has an angular radius of about 50° and hence is seen outside of the primary bow. This bow results from light that has undergone two internal reflections within the water drop. Higher-order rainbows, resulting from three or more internal reflections, are exceedingly weak and hence are rarely observed.

Occasionally, faintly coloured rings are seen just inside of the primary bow. These are called supernumerary rainbows; they owe their origin to interference effects on the light rays emerging from the water droplet after one internal reflection.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#491 2019-09-03 01:29:50

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 51,563

Re: Miscellany

399) Typewriter

Typewriter, any of various machines for writing characters similar to those made by printers’ types, especially a machine in which the characters are produced by steel types striking the paper through an inked ribbon with the types being actuated by corresponding keys on a keyboard and the paper being held by a platen that is automatically moved along with a carriage when a key is struck.

The invention of various kinds of machines was attempted in the 19th century. Most were large and cumbersome, some resembling pianos in size and shape. All were much slower to use than handwriting. Finally, in 1867, the American inventor Christopher Latham Sholes read an article in the journal Scientific American describing a new British-invented machine and was inspired to construct what became the first practical typewriter. His second model, patented on June 23, 1868, wrote at a speed far exceeding that of a pen. It was a crude machine, but Sholes added many improvements in the next few years, and in 1873 he signed a contract with E. Remington and Sons, gunsmiths, of Ilion, New York, for manufacture. The first typewriters were placed on the market in 1874, and the machine was soon renamed the Remington. Among its original features that were still standard in machines built a century later were the cylinder, with its line-spacing and carriage-return mechanism; the escapement, which causes the letter spacing by carriage movement; the arrangement of the typebars so as to strike the paper at a common centre; the actuation of the typebars by means of key levers and connecting wires; printing through an inked ribbon; and the positions of the different characters on the keyboard, which conform almost exactly to the arrangement that is now universal. Mark Twain purchased a Remington and became the first author to submit a typewritten book manuscript.

The first typewriter had no shift-key mechanism—it wrote capital letters only. The problem of printing both capitals and small letters without increasing the number of keys was solved by placing two types, a capital and lowercase of the same letter, on each bar, in combination with a cylinder-shifting mechanism. The first shift-key typewriter—the Remington Model 2—appeared on the market in 1878. Soon after appeared the so-called double-keyboard machines, which contained twice the number of keys—one for every character, whether capital or small letter. For many years the double keyboard and the shift-key machines competed for popular favour, but the development of the so-called touch method of typing, for which the compact keyboard of the shift-key machines was far better suited, decided the contest.

Another early issue concerned the relative merits of the typebar and the type wheel, first applied in cylinder models brought out in the 1880s and later. In modern machines of this variety the type faces are mounted on a circle or segment, the operation of the keys brings each type to correct printing position, and the imprint of type on paper is produced by a trigger action. The type-wheel machines offer an advantage in the ease with which the type segments may be changed, thus extending the range and versatility of the machine.

On nearly all typewriters the printing is done through an inked ribbon, which is fitted on spools, travels with the operation of the machine, and reverses automatically when one spool becomes completely unwound. On other machines an inking pad is used, the type contacting the pad prior to printing.

Noiseless Typewriters

The noiseless linkage is a variation of the conventional typebar linkage causing the typebar to strike the platen at a lower velocity but with the same momentum. Although it produces less noise than the conventional typewriter, the noiseless typewriter cannot produce as fine an impression or as many carbon copies.

Electric Typewriters

A significant advance in the typewriter field was the development of the electric typewriter, basically a mechanical typewriter with the typing stroke powered by an electric-motor drive. The typist initiates the key stroke, the carriage motion, and other controls by touching the proper key. The actuation is performed by the proper linkage clutching to a constantly rotating drive shaft. Advantages of this system include lighter touch, faster and more uniform typing, more legible and numerous carbon copies, and less operator fatigue. Especially valuable as an office machine capable of a high volume of output, electric typewriters are produced by all major typewriter manufacturers.