Math Is Fun Forum

You are not logged in.

- Topics: Active | Unanswered

#1051 2021-06-15 00:24:09

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1029) Uncertainty principle

Uncertainty principle, also called Heisenberg uncertainty principle or indeterminacy principle, statement, articulated (1927) by the German physicist Werner Heisenberg, that the position and the velocity of an object cannot both be measured exactly, at the same time, even in theory. The very concepts of exact position and exact velocity together, in fact, have no meaning in nature.

Ordinary experience provides no clue of this principle. It is easy to measure both the position and the velocity of, say, an automobile, because the uncertainties implied by this principle for ordinary objects are too small to be observed. The complete rule stipulates that the product of the uncertainties in position and velocity is equal to or greater than a tiny physical quantity, or constant (h/(4π), where h is Planck’s constant, or about 6.6 × {10}^{-34} joule-second). Only for the exceedingly small masses of atoms and subatomic particles does the product of the uncertainties become significant.

Any attempt to measure precisely the velocity of a subatomic particle, such as an electron, will knock it about in an unpredictable way, so that a simultaneous measurement of its position has no validity. This result has nothing to do with inadequacies in the measuring instruments, the technique, or the observer; it arises out of the intimate connection in nature between particles and waves in the realm of subatomic dimensions.

The uncertainty principle arises from the wave-particle duality. Every particle has a wave associated with it; each particle actually exhibits wavelike behaviour. The particle is most likely to be found in those places where the undulations of the wave are greatest, or most intense. The more intense the undulations of the associated wave become, however, the more ill-defined becomes the wavelength, which in turn determines the momentum of the particle. So a strictly localized wave has an indeterminate wavelength; its associated particle, while having a definite position, has no certain velocity. A particle wave having a well-defined wavelength, on the other hand, is spread out; the associated particle, while having a rather precise velocity, may be almost anywhere. A quite accurate measurement of one observable involves a relatively large uncertainty in the measurement of the other.

The uncertainty principle is alternatively expressed in terms of a particle’s momentum and position. The momentum of a particle is equal to the product of its mass times its velocity. Thus, the product of the uncertainties in the momentum and the position of a particle equals h/(4π) or more. The principle applies to other related (conjugate) pairs of observables, such as energy and time: the product of the uncertainty in an energy measurement and the uncertainty in the time interval during which the measurement is made also equals h/(4π) or more. The same relation holds, for an unstable atom or nucleus, between the uncertainty in the quantity of energy radiated and the uncertainty in the lifetime of the unstable system as it makes a transition to a more stable state.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1052 2021-06-16 00:42:23

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1030) Agoraphobia

Fear of Open or Crowded Spaces Phobia – Agoraphobia

Agoraphobia is the irrational fear of having a panic (or anxiety) attack in a place that may be difficult to escape from. Before we learn about the causes, symptoms and treatment of this phobia, let us first see a few myths associated with it and the actual facts.

Myths about Agoraphobia

• People with the fear of open spaces always remain housebound– Many sufferers of Agoraphobia actually prefer crowded spaces than being left alone at home. A majority of these patients may have milder symptoms of Agoraphobia. If one is housebound for months or years, then his/her Agoraphobia can be classified as being extreme.

• Agoraphobia is only the fear of crowded spaces– As mentioned above; some individuals are known to fear crowds while others to prefer them.

• Fear of enclosed spaces in not Agoraphobia, only claustrophobia (the fear of enclosed spaces)– Many individuals with Agoraphobia are also known to fear enclosed spaces but they might have other fear symptoms as well.

• Agoraphobia is the fear of open spaces and public places– More than the fear of being in an open space; the phobic tends to fear a “symptom-attack”- a rush of symptoms and sensations that s/he is unable to deal with.

• Agoraphobia is always a fear of panic attack– In Agoraphobia, it is not just ‘panic’ that one fears but several other symptoms. For example, a person might feel nauseated in a crowded space and fear not being able to reach the bathroom on time to throw up. Thus, the sufferer might “learn to feel or expect to feel something disturbing” in a particular situation and hence try to avoid the situations as much as possible.

Causes of Agoraphobia or the fear of open/crowded spaces

There is no single cause for the fear of open or crowded spaces. Researchers believe that a number of physical and psychological factors may be responsible for this phobia.

• In the majority of cases, an underlying ‘panic disorder’ may be responsible for Agoraphobia. A panic disorder is characterized by an intense and irrational fear that can cause the sufferer to lose control, cry, shake and have thoughts about dying. In his/her mind, the sufferer then links the attack to situations and then tries to avoid those situations completely.

• A research is also suggesting a possible link between long term tranquilizer or sleeping pill usage with Agoraphobia.

• Individuals with difficulty of spatial orientation and balance (or those with weaker vestibular functions) are also known to experience the extreme fear of crowded or open spaces.

• A history of alcohol or drug abuse, traumatic childhood experiences, recent life changes such as death, divorce, relationship difficulties, war, explosion, earthquakes etc can bring on the fear of open or crowded spaces.

Symptoms of Agoraphobia

The symptoms of this phobia can be classified into physical and psychological symptoms.

Physical symptoms:

• Hyperventilating or rapid/shallow breathing

• Feeling of choking or difficulty swallowing

• Sweating

• Shaking and trembling

• Nausea and other gastrointestinal distress

• Dizziness or lightheadedness

• Ringing or buzzing in the ears

Psychological symptoms

• Fear of losing control or going crazy

• Fear of dying

• Feeling ‘unreal’ or detached from oneself

• Feelings of depression, dread or anxiety

• Having low self esteem or low confidence

Treatment for Agoraphobia

It is essential to treat Agoraphobia early on, since, left untreated, it may take a more serious form and even make the sufferer depressed

There are several treatment options for dealing with the fear of open or crowded spaces. Of these, it is best to rely on the self help techniques rather than taking medications as the latter can have withdrawal symptoms and other side effects.

Self help techniques for dealing with panic symptoms

• Breathing slowly and counting to ten while repeating the word ‘relax’ in calm and soothing manner. This is one of the expert recommended self help techniques that have been proven highly effective in managing panic symptoms.

• Slowly exposing oneself to one’s fears and also writing down things that make one feels fearful. This might turn out to be difficult in the beginning but gradually one can overcome the fear of crowded or open spaces.

• Educating self – There are many books and case studies available online and offline that can inspire one to fight their Agoraphobia.

Other than these self help methods, one can also opt for CBT/cognitive behavior or behavior therapy, guided imagery, counseling, talk therapy and group therapy. Taking baby steps is the key to overcoming Agoraphobia.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1053 2021-06-17 00:18:32

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1031) Boyle's law

Boyle’s law, also called Mariotte’s law, a relation concerning the compression and expansion of a gas at constant temperature. This empirical relation, formulated by the physicist Robert Boyle in 1662, states that the pressure (p) of a given quantity of gas varies inversely with its volume (v) at constant temperature; i.e., in equation form, pv = k, a constant. The relationship was also discovered by the French physicist Edme Mariotte (1676).

The law can be derived from the kinetic theory of gases assuming a perfect (ideal) gas. Real gases obey Boyle’s law at sufficiently low pressures, although the product pv generally decreases slightly at higher pressures, where the gas begins to depart from ideal behaviour.

Boyle’s Law is a basic law in chemistry describing the behavior of a gas held at a constant temperature. The law, discovered by Robert A. Boyle in 1662, states that at a fixed temperature, the volume of gas is inversely proportional to the pressure exerted by the gas. In other words, when a gas is pumped into an enclosed space, it will shrink to fit into that space, but the pressure that gas puts on the container will increase.

Perhaps a more straightforward way is to say Boyle's law is the relationship between pressure and volume. Mathematically, Boyle’s law can be written as pV=k, where p is the pressure of the gas, V is the volume of the gas, and k is a constant.

An example of Boyle’s law in action can be seen in a balloon. Air is blown into the balloon; the pressure of that air pushes on the rubber, making the balloon expand. If one end of the balloon is squeezed, making the volume smaller, the pressure inside increased, making the un-squeezed part of the balloon expand out. There is a limit to how much the air/gas can be compressed, however, because eventually the pressure becomes so great that it causes the balloon to break.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1054 2021-06-18 00:04:53

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1032) Charles's law

Charles’s law, a statement that the volume occupied by a fixed amount of gas is directly proportional to its absolute temperature, if the pressure remains constant. This empirical relation was first suggested by the French physicist J.-A.-C. Charles about 1787 and was later placed on a sound empirical footing by the chemist Joseph-Louis Gay-Lussac. It is a special case of the general gas law and can be derived from the kinetic theory of gases under the assumption of a perfect (ideal) gas. Measurements show that at constant pressure the thermal expansion of real gases, at sufficiently low pressure and high temperature, conforms closely to Charles’s law.

The physical principle known as Charles' law states that the volume of a gas equals a constant value multiplied by its temperature as measured on the Kelvin scale (zero Kelvin corresponds to -273.15 degrees Celsius).

Charles's law, a statement that the volume occupied by a fixed amount of gas is directly proportional to its absolute temperature, if the pressure remains constant. It is a special case of the general gas law and can be derived from the kinetic theory of gases under the assumption of a perfect (ideal) gas.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1055 2021-06-19 00:07:48

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1033) Ohm's law

Ohm’s law, description of the relationship between current, voltage, and resistance. The amount of steady current through a large number of materials is directly proportional to the potential difference, or voltage, across the materials. Thus, if the voltage V (in units of volts) between two ends of a wire made from one of these materials is tripled, the current I (amperes) also triples; and the quotient V/I remains constant. The quotient V/I for a given piece of material is called its resistance, R, measured in units named ohms. The resistance of materials for which Ohm’s law is valid does not change over enormous ranges of voltage and current. Ohm’s law may be expressed mathematically as V/I = R. That the resistance, or the ratio of voltage to current, for all or part of an electric circuit at a fixed temperature is generally constant had been established by 1827 as a result of the investigations of the German physicist Georg Simon Ohm.

Alternate statements of Ohm’s law are that the current I in a conductor equals the potential difference V across the conductor divided by the resistance of the conductor, or simply I = V/R, and that the potential difference across a conductor equals the product of the current in the conductor and its resistance, V = IR. In a circuit in which the potential difference, or voltage, is constant, the current may be decreased by adding more resistance or increased by removing some resistance. Ohm’s law may also be expressed in terms of the electromotive force, or voltage, E, of the source of electric energy, such as a battery. For example, I = E/R.

With modifications, Ohm’s law also applies to alternating-current circuits, in which the relation between the voltage and the current is more complicated than for direct currents. Precisely because the current is varying, besides resistance, other forms of opposition to the current arise, called reactance. The combination of resistance and reactance is called impedance, Z. When the impedance, equivalent to the ratio of voltage to current, in an alternating current circuit is constant, a common occurrence, Ohm’s law is applicable. For example, V/I = Z.

With further modifications Ohm’s law has been extended to the constant ratio of the magnetomotive force to the magnetic flux in a magnetic circuit.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1056 2021-06-20 00:04:30

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

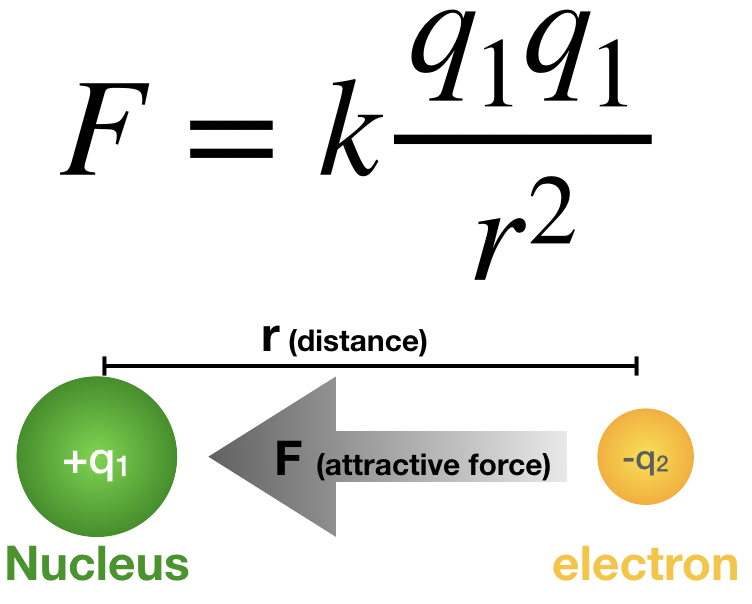

1034) Coulomb's law

Coulomb’s law, mathematical description of the electric force between charged objects. Formulated by the 18th-century French physicist Charles-Augustin de Coulomb, it is analogous to Isaac Newton’s law of gravity.

Both gravitational and electric forces decrease with the square of the distance between the objects, and both forces act along a line between them. In Coulomb’s law, however, the magnitude and sign of the electric force are determined by the electric charge, rather than the mass, of an object. Thus, charge determines how electromagnetism influences the motion of charged objects. Charge is a basic property of matter. Every constituent of matter has an electric charge with a value that can be positive, negative, or zero. For example, electrons are negatively charged, and atomic nuclei are positively charged. Most bulk matter has an equal amount of positive and negative charge and thus has zero net charge.

According to Coulomb, the electric force for charges at rest has the following properties:

1. Like charges repel each other; unlike charges attract. Thus, two negative charges repel one another, while a positive charge attracts a negative charge.

2. The attraction or repulsion acts along the line between the two charges.

3. The size of the force varies inversely as the square of the distance between the two charges. Therefore, if the distance between the two charges is doubled, the attraction or repulsion becomes weaker, decreasing to one-fourth of the original value. If the charges come 10 times closer, the size of the force increases by a factor of 100.

4. The size of the force is proportional to the value of each charge. The unit used to measure charge is the coulomb (C). If there were two positive charges, one of 0.1 coulomb and the second of 0.2 coulomb, they would repel each other with a force that depends on the product 0.2 × 0.1. Thus, if each of the charges were reduced by one-half, the repulsion would be reduced to one-quarter of its former value.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1057 2021-06-21 00:08:33

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1035) Ampère's law

Ampère’s law, one of the basic relations between electricity and magnetism, stating quantitatively the relation of a magnetic field to the electric current or changing electric field that produces it. The law is named in honour of André-Marie Ampère, who by 1825 had laid the foundation of electromagnetic theory. An alternative expression of the Biot-Savart law (q.v.), which also relates the magnetic field and the current that produces it, Ampère’s law is generally stated formally in the language of calculus: the line integral of the magnetic field around an arbitrarily chosen path is proportional to the net electric current enclosed by the path. James Clerk Maxwell is responsible for this mathematical formulation and for the extension of the law to include magnetic fields that arise without electric current, as between the plates of a capacitor, or condenser, in which the electric field changes with the periodic charging and discharging of the plates but in which no passage of electric charge occurs. Maxwell also showed that even in empty space a varying electric field is accompanied by a changing magnetic field. In this more general form, the so-called Ampère-Maxwell law is one of the four Maxwell equations that define electromagnetism.

Ampere's Law can be stated as:

“The magnetic field created by an electric current is proportional to the size of that electric current with a constant of proportionality equal to the permeability of free space.”

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1058 2021-06-22 00:07:22

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1036) Newton's law of cooling

Newton's law of cooling states that ‘the rate of heat loss of a body is directly proportional to the difference in the temperatures between the body and its surroundings’. The law is frequently qualified to include the condition that the temperature difference is small and the nature of heat transfer mechanism remains the same. As such, it is equivalent to a statement that the heat transfer coefficient, which mediates between heat losses and temperature differences, is a constant. This condition is generally met in heat conduction (where it is guaranteed by Fourier's law) as the thermal conductivity of most materials is only weakly dependent on temperature. In convective heat transfer, Newton's Law is followed for forced air or pumped fluid cooling, where the properties of the fluid do not vary strongly with temperature, but it is only approximately true for buoyancy-driven convection, where the velocity of the flow increases with temperature difference. Finally, in the case of heat transfer by thermal radiation, Newton's law of cooling holds only for very small temperature differences, and a more accurate description is given by Planck's Law.

Sir Isaac Newton did not originally state his law in the above form in 1701, when it was originally formulated. Rather, using today's terms, Newton noted after some mathematical manipulation that ‘the rate of temperature change’ of a body is proportional to the difference in temperatures between the body and its surroundings. This final simplest version of the law given by Newton himself, was partly due to confusion in Newton's time between the concepts of heat and temperature, which would not be fully disentangled until much later.

When stated in terms of temperature differences, Newton's law (with several further simplifying assumptions, such as a low Biot number and a temperature-independent heat capacity) results in a simple differential equation temperature-difference as a function of time. The solution to that equation describes an exponential decrease of temperature-difference over time. This characteristic decay of the temperature-difference is also associated with Newton's law of cooling.

Relationship to mechanism of cooling

Convection cooling is sometimes said to be governed by "Newton's law of cooling." This use is based on a work by Sir Isaac Newton published anonymously in 1701 as "Scala graduum Caloris. Calorum Descriptiones & signa." in Philosophical Transactions, volume 22, issue 270.

When the heat transfer coefficient is independent, or relatively independent, of the temperature difference between object and environment, Newton's law is followed. This independence is sometimes the case, but is not generally so. The law holds well for forced air and pumped liquid cooling, where the fluid velocity does not rise with increasing temperature difference. Newton's law is most closely obeyed in purely conduction-type cooling. However, the heat transfer coefficient is a function of the temperature difference in natural convective (buoyancy driven) heat transfer. In that case, Newton's law only approximates the result when the temperature difference is relatively small. Newton himself realized this limitation.

A correction to Newton's law concerning convection for larger temperature differentials by including an exponent, was made in 1817 by Dulong and Petit. (These men are better-known for their formulation of the Dulong–Petit law concerning the molar specific heat capacity of a crystal.)

Another situation which also does not obey Newton's law, is radiative heat transfer, being better described by Planck's law as varying with the 4th power of absolute temperature.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1059 2021-06-23 00:20:32

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

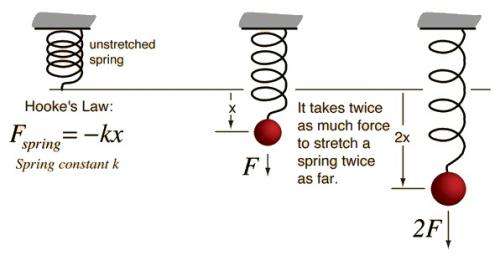

1037) Hooke's law

Hooke’s law, law of elasticity discovered by the English scientist Robert Hooke in 1660, which states that, for relatively small deformations of an object, the displacement or size of the deformation is directly proportional to the deforming force or load. Under these conditions the object returns to its original shape and size upon removal of the load. Elastic behaviour of solids according to Hooke’s law can be explained by the fact that small displacements of their constituent molecules, atoms, or ions from normal positions is also proportional to the force that causes the displacement.

The deforming force may be applied to a solid by stretching, compressing, squeezing, bending, or twisting. Thus, a metal wire exhibits elastic behaviour according to Hooke’s law because the small increase in its length when stretched by an applied force doubles each time the force is doubled. Mathematically, Hooke’s law states that the applied force F equals a constant k times the displacement or change in length x, or F = kx. The value of k depends not only on the kind of elastic material under consideration but also on its dimensions and shape.

At relatively large values of applied force, the deformation of the elastic material is often larger than expected on the basis of Hooke’s law, even though the material remains elastic and returns to its original shape and size after removal of the force. Hooke’s law describes the elastic properties of materials only in the range in which the force and displacement are proportional. Sometimes Hooke’s law is formulated as F = −kx. In this expression F no longer means the applied force but rather means the equal and oppositely directed restoring force that causes elastic materials to return to their original dimensions.

Hooke’s law may also be expressed in terms of stress and strain. Stress is the force on unit areas within a material that develops as a result of the externally applied force. Strain is the relative deformation produced by stress. For relatively small stresses, stress is proportional to strain.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1060 2021-06-24 00:19:13

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1038) Snell's law

Snell’s law, in optics, a relationship between the path taken by a ray of light in crossing the boundary or surface of separation between two contacting substances and the refractive index of each. This law was discovered in 1621 by the Dutch astronomer and mathematician Willebrord Snell (also called Snellius). The account of Snell’s law went unpublished until its mention by Christiaan Huygens in his treatise on light. n1 and n2 represent the indices of refraction for the two media, and α1 and α2 are the angles of incidence and refraction that the ray R makes with the normal (perpendicular) line NN at the boundary. Snell’s law asserts that n1/n2 = sin α2/sin α1.

Because the ratio n1/n2 is a constant for any given wavelength of light, the ratio of the two sines is also a constant for any angle. Thus, the path of a light ray is bent toward the normal when the ray enters a substance with an index of refraction higher than the one from which it emerges; and because the path of a ray of light is reversible, the ray is bent away from the normal when entering a substance of lower refractive index.

The reason light is refracted in going from one medium to another.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1061 2021-06-25 00:13:29

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

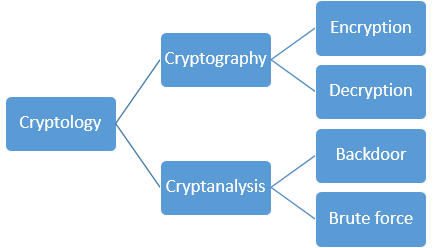

1039) Cryptography and Cryptology

Cryptography, Practice of the enciphering and deciphering of messages in secret code in order to render them unintelligible to all but the intended receiver. Cryptography may also refer to the art of cryptanalysis, by which cryptographic codes are broken. Collectively, the science of secure and secret communications, involving both cryptography and cryptanalysis, is known as cryptology. The principles of cryptography are today applied to the encryption of fax, television, and computer network communications. In particular, the secure exchange of computer data is of great importance to banking, government, and commercial communications.

Cryptology, science concerned with data communication and storage in secure and usually secret form. It encompasses both cryptography and cryptanalysis.

The term cryptology is derived from the Greek kryptós (“hidden”) and lógos (“word”). Security obtains from legitimate users being able to transform information by virtue of a secret key or keys—i.e., information known only to them. The resulting cipher, although generally inscrutable and not forgeable without the secret key, can be decrypted by anyone knowing the key either to recover the hidden information or to authenticate the source. Secrecy, though still an important function in cryptology, is often no longer the main purpose of using a transformation, and the resulting transformation may be only loosely considered a cipher.

Cryptography (from the Greek kryptós and gráphein, “to write”) was originally the study of the principles and techniques by which information could be concealed in ciphers and later revealed by legitimate users employing the secret key. It now encompasses the whole area of key-controlled transformations of information into forms that are either impossible or computationally infeasible for unauthorized persons to duplicate or undo.

Cryptanalysis (from the Greek kryptós and analýein, “to loosen” or “to untie”) is the science (and art) of recovering or forging cryptographically secured information without knowledge of the key. Cryptology is often—and mistakenly—considered a synonym for cryptography and occasionally for cryptanalysis, but specialists in the field have for years adopted the convention that cryptology is the more inclusive term, encompassing both cryptography and cryptanalysis.

Cryptography was initially only concerned with providing secrecy for written messages, especially in times of war. Its principles apply equally well, however, to securing data flowing between computers or data stored in them, to encrypting facsimile and television signals, to verifying the identity of participants in electronic commerce (e-commerce) and providing legally acceptable records of those transactions. Because of this broadened interpretation of cryptography, the field of cryptanalysis has also been enlarged.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1062 2021-06-26 00:30:46

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1040) Salt

Salt (NaCl), sodium chloride, mineral substance of great importance to human and animal health, as well as to industry. The mineral form halite, or rock salt, is sometimes called common salt to distinguish it from a class of chemical compounds called salts.

Salt is essential to the health of both people and animals. Table salt, used universally as a seasoning, is fine-grained and of high purity. To ensure that this hygroscopic (i.e., water-attracting) substance will remain free-flowing when exposed to the atmosphere, small quantities of sodium aluminosilicate, tricalcium phosphate, or magnesium silicate are added. Iodized salt—that is, salt to which small quantities of potassium iodide have been added—is widely used in areas where iodine is lacking from the diet, a deficiency that can cause swelling of the thyroid gland, commonly called goitre. Livestock also require salt; it is often made available in solid blocks.

The meat-packing, sausage-making, fish-curing, and food-processing industries use salt as a preservative or seasoning or both. It is employed for curing and preserving hides and as a brine for refrigeration.

In the chemical industry, salt is required in the manufacture of sodium bicarbonate (baking soda), sodium hydroxide (caustic soda), hydrochloric acid, chlorine, and many other chemicals. Salt is also employed in soap, glaze, and porcelain enamel manufacture and enters into metallurgical processes as a flux (a substance promoting fusing of metals).

When applied to snow or ice, salt lowers the melting point of the mixture. Thus, large amounts are used in northern climates to help rid thoroughfares of accumulated snow and ice. Salt is used in water-softening equipment that removes calcium and magnesium compounds from water.

History Of Use

In some parts of the Western Hemisphere and in India, the use of salt was introduced by Europeans, but in parts of central Africa it is still a luxury available only to the rich. Where people live mainly on milk and raw or roasted meat (so that its natural salts are not lost), sodium chloride supplements are unnecessary; nomads with their flocks of sheep or herds of cattle, for example, never eat salt with their food. On the other hand, people who live mostly on cereal, vegetable, or boiled meat diets require supplements of salt.

The habitual use of salt is intimately connected with the advance from nomadic to agricultural life, a step in civilization that profoundly influenced the rituals and cults of almost all ancient nations. The gods were worshipped as the givers of the kindly fruits of the earth, and salt was usually included in sacrificial offerings consisting wholly or partly of cereal elements. Such offerings were prevalent among the Greeks and Romans and among a number of the Semitic peoples.

Covenants were ordinarily made over a sacrificial meal, in which salt was a necessary element. The preservative qualities of salt made it a peculiarly fitting symbol of an enduring compact, sealing it with an obligation to fidelity. The word salt thus acquired connotations of high esteem and honour in ancient and modern languages. Examples include the Arab avowal “There is salt between us,” the Hebrew expression “to eat the salt of the palace,” and the modern Persian phrase namak ḥarām, “untrue to salt” (i.e., disloyal or ungrateful). In English the term “salt of the earth” describes a person held in high esteem.

Salt contributes greatly to our knowledge of the ancient highways of commerce. One of the oldest roads in Italy is the Via Salaria (Salt Route) over which Roman salt from Ostia was carried into other parts of Italy. Herodotus tells of a caravan route that united the salt oases of the Libyan Desert. The ancient trade between the Aegean and the Black Sea coast of southern Russia was largely dependent on the salt pans (ponds for evaporating seawater to obtain salt) at the mouth of the Dnieper River and on the salt fish brought from this district.

Cakes of salt have been used as money in Ethiopia and elsewhere in Africa and in Tibet. In the Roman army an allowance of salt was made to officers and men; in imperial times, this salarium (from which the English word salary is derived) was converted into an allowance of money for salt.

China, the United States, India, Germany, Canada, and Australia are the world’s largest salt producers in the early 21st century.

Occurrence

Seawater

Though the material that gives seawater its salty flavour is composed of many substances, sodium chloride, or common salt, is by far the predominant compound. On the assumption that 1 gallon (about 4 litres) of seawater contains 0.231 pound (about 105 grams) of salt and that rock salt on the average is 2.17 times as dense as water, it has been estimated that if the oceans of the world were completely dried up, they would yield at least 4.5 million cubic miles of rock salt, or about 14.5 times the bulk of the entire continent of Europe above the high-water mark.

Seawater contains on the average about 3 percent salt, although the actual concentration varies from about 1 percent (in the polar seas) to 5 percent. Enclosed waters such as the Mediterranean and Red seas contain a higher proportion of salt than does the open ocean at the same latitude. Irrespective of the source of the seawater, salt obtained by the evaporation of seawater has the following composition: sodium chloride 77.76 percent, magnesium chloride 10.88 percent, magnesium sulfate 4.74 percent, calcium sulfate 3.60 percent, potassium chloride 2.46 percent, magnesium bromide 0.22 percent, and calcium carbonate 0.34 percent.

Natural brines

Brine is water containing a high concentration of salt. Natural brines of commercial importance are found in the Dead Sea as well as in Austria, France, Germany, India, the United States, and the United Kingdom. Salt in brines is nearly always accompanied by chlorides and sulfates of potassium, calcium, and magnesium; carbonates and the element bromine often are present as well.

The Dead Sea, which covers an area of 1,020 square km (394 square miles), contains approximately 12,650,000,000 tons of salt. The Jordan River, which contains only 35 parts of salt per 100,000 parts of water, adds 850,000 tons of salt to this total each year.

The concentration of salts in the Dead Sea varies from 270 to 300 parts per thousand to a depth of 40 metres (130 feet); it increases gradually from 40 to 100 metres (130 to 330) feet and remains a fairly constant 332 parts per thousand below 100 metres. Dead Sea water is relatively free from sulfates and has a high proportion of potassium and bromine. Because atmospheric conditions favour evaporation by sunlight (solar evaporation) for about eight months of the year, the production of salt, potassium, and bromine is feasible in the Dead Sea area. The process used for recovery of salt and potash is similar to that described below under Salt manufacture. The Indian brines at Khārāghoda resemble seawater in the character of their dissolved salts but are much more concentrated and in some cases virtually saturated; that is, they have dissolved all the salt they can.

Certain natural brines occurring in the United Kingdom and the United States are of special interest because they contain salts, such as the chlorides of barium and strontium, that are not usually found in brines. Special processing methods are required to produce salt from such brines. In Britain these unusual brines are found at great depths during test drillings for petroleum, while in the United States such brines occur in deep wells in several places.

Rock salt

Rock salt is crystalline sodium chloride, called halite by mineralogists. It occurs widely in the form of rock masses and beds and is abundant in rocks from all geologic periods. Because of its great solubility in water, it occurs under extremely thick cover in humid regions but lies close to the surface in arid regions.

All major rock salt deposits originated from the evaporation of seawater at some time during the geologic past. Approximately 78 percent of the mineral matter in normal seawater is sodium chloride. Upon evaporation of about nine-tenths of the volume of seawater, rock salt is precipitated. Calcium sulfate (gypsum and anhydrite) and potassium and magnesium salts also are precipitated. Deposits are found in beds from a few feet to many hundreds of feet thick. The ages of these beds range through much of geologic time. Because evaporation of a large quantity of seawater leaves only a small amount of salt, it is theorized that many extremely thick rock salt beds were deposited in partly enclosed arms of the seas in which evaporation was greater than the inflow of salt water. A barrier on the seafloor at the entrance to the basin prevented the outflow of the concentrated saline water.

Such bedded salt deposits occur in the Punjab Salt Range in Pakistan and in Iran; however, these deposits have been little exploited. Similar deposits in the United States and Canada are worked extensively for both industrial and domestic use. Other important salt deposits, usually classified by the age of the surrounding rock, are found in Germany, Nova Scotia, the sub-Carpathian region extending from Poland through Hungary and Romania, and the province of Sichuan in China, where salt wells have been in existence for more than 2,000 years.

Another economically important type of rock salt deposit is the salt domes, which were formed when earth pressure forced up plugs of rock salt measuring approximately a mile across. The domes appear to result from pressure, which pushes the salt up through the rocks from depths as great as 50,000 feet (15,000 metres). Many domes occur at shallow depths and are extensively mined. Domes in the sub-Carpathian region of Europe have been worked since ancient times. The North German Plain has many extensively mined domes, which are thought to have originated below 6,000 feet; domes also are abundant along the U.S. Gulf Coast. Rock salt may be obtained from domes by the usual mining methods or by drilling wells into the salt strata and pumping water down to dissolve the salt; the brine is then returned to the surface, where it is processed like natural brine.

Salt Manufacture

At one time almost all the salt used in commerce was produced from the evaporation of seawater, and sea salt still is a staple commodity in many maritime countries, especially where the climate is dry and the summer is long. Commercial salt is manufactured from rock salt, as well as from seawater and other natural and artificial brines. Most of the artificial brines are obtained by pumping water into underground salt beds. A considerable amount of brine itself is used directly in industrial countries.

Manufacture from rock salt

The beds of rock salt are mined or quarried by the usual excavation methods, depending on the depths and thicknesses of the deposits and on local conditions. The mined rock salt sometimes is dissolved and the salt manufactured by treatment of the brine, as described below. The method affords opportunities for purification of the salt. When the rock salt is of a high degree of purity, as in Poland and the United States, the salt may be ground, screened, and marketed without further processing. The salt is mined in large lumps that are first crushed, then more finely ground and screened by size into various grades; the salt is then bulk-loaded into trucks, hoppers, or barges or loaded into bags for further handling. Bulk handling has been greatly facilitated by the use of anticaking agents which allow the salt to be stored uncovered and outdoors without becoming a hard mass again.

Manufacture from seawater and brines

Only a certain quantity of salt will dissolve in water at any given temperature. Once the solution contains as much salt as it can hold, it is said to be saturated; any further additions of salt will not dissolve.

Evaporation is the reverse of this process. When an aqueous solution of several salts (seawater, for example) is evaporated, each of the salts precipitates as it reaches its point of saturation in the solution. Thus, the different salts in seawater will precipitate at different times, forming layers on the bottom of the evaporating pond. For seawater and many brines, the order of deposition is calcium carbonate, calcium sulfate, sodium chloride, magnesium sulfate, potassium magnesium chloride, and magnesium chloride.

Solar evaporation

In maritime countries where there is a negative evaporation rate—i.e., the amount of water evaporating exceeds the amount of rainfall by at least 75 cm (about 30 inches)—salt is produced by solar evaporation from seawater. The processes used are similar in general principle from country to country, but details of equipment vary from sophisticated in the United States to quite primitive in developing nations.

A preliminary concentration is usually accomplished by allowing the seawater to flow through a series of gates constructed of wood or a combination of wood and concrete into a series of shallow ponds separated by dikes. In these ponds the solution is concentrated to a specific gravity of about 1.22; this means that a given volume of brine is 1.22 times as dense as a given volume of pure water. At this stage, suspended impurities such as sand, clay, and the less soluble salts such as calcium carbonate, or chalk, and calcium sulfate are removed. Solar evaporation of the Dead Sea water is hastened by adding dye to the water. The dye permits more heat to be absorbed from sunlight in thinner layers of brine so that shallow ponds may be used and the penetration of brine into the ground is reduced.

Once it has been concentrated, the brine is run through a series of crystallizing pans, usually four in number, where the salt is deposited as evaporation proceeds. In the first crystallizing pan, the brine is concentrated to a specific gravity of 1.23 and remains partly contaminated with calcium sulfate. The specific gravity of the solution in the pan increases slowly during crystallization of the salt, reaching 1.24 in the second pan. In the third pan the specific gravity of the solution reaches 1.25, and the salt deposited there contains small amounts of magnesium sulfate as an impurity. The final solution, termed bitterns, has a specific gravity of 1.25–1.26 and is used in some countries (United States and Israel) in the manufacture of potash, bromine, epsom salts (magnesium sulfate), and magnesium chloride.

In developing countries the salt in each crystallizing pan is raked into rows, where it is allowed to drain for several days. After that it is collected into heaps, drained again, lifted from the pans, and finally dried. In industrial countries the salt is harvested mechanically and washed with saturated brine. It is then dewatered, washed with fresh water, and stored for further processing or direct sale.

Use of artificial heat

In areas where bedded deposits can be solution-mined, evaporated salt is recovered from these solutions with artificial heat. Some evaporated salt also is made from natural brine or solar salt. Formerly, brine was concentrated in open pans over fire. More recently, steam-jacketed vessels have been used. The largest amount of salt produced in the colder climates is rock salt. The largest amount of evaporated salt is produced by multiple-effect vacuum evaporators, and an important quantity is made in so-called open crystallizers or grainers that produce a type of crystal preferred for use in some of the food industries. The brine, natural or artificial, is first pumped into settling tanks, where calcium and magnesium compounds may be removed by chemical treatment. In grainer operations the settled and filtered brine is delivered to the grainer, a long open trough heated with steam coils. The brine is fed into the grainer at approximately the same rate at which evaporation is taking place and at a temperature only slightly below that of the brine in the grainer. The residue of brine, or bitterns, may be removed continuously, once a day, or less often. Evaporation occurs at the surface of the liquid, and the crystals originate there. They remain at the surface, held up by the surface tension of the brine. The crystal grows at the top edges, becoming a small inverted hollow pyramid, or hopper. Eventually the hopper sinks and ceases to grow. When the crystals are recovered, the salt is largely in the form of flakes, hence the name flake salt.

When multiple-effect evaporators are used, the vacuum in each vessel is adjusted so that the vapour from the first vessel is hot enough to boil the brine in the second, the vapour from the second supplying the heat to operate the third vessel or effect. The brine is usually sent through the stages or effects in succession, although in the case of salt manufacture fresh brine may be fed to each stage if desired. With open pans, 4,500 to 5,400 kg (10,000 to 12,000 pounds) of steam are required to produce 900 kg (1 ton) of salt. With triple-effect evaporation, 630 kg (1,400 pounds) of steam produce 1 ton of salt.

The Alberger process is partially a vacuum-pan and partially a grainer operation in which cubic crystals are formed in the solution fed to the grainer pans by a partial vacuum-pan evaporation. These seed crystals in the grainer produce a salt that is a mixture of the grainer-type flake and the flake grown on seed crystals. About 1,360 kg (3,000 pounds) of steam are required to produce one ton of salt. Salt from the Alberger process is centrifuged (spun) from the brine and then dried. Table salt may have small amounts of aluminum calcium silicate, calcium silicate, magnesium silicate, tricalcium silicate, magnesium carbonate, or tricalcium phosphate added to keep it free-flowing. Iodized salt has potassium iodide added. In some countries yellow prussiate of soda, to prevent caking, is added in minute amounts as regulated by the government.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1063 2021-06-27 00:27:01

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1041) Artesian well

Artesian well, well from which water flows under natural pressure without pumping. It is dug or drilled wherever a gently dipping, permeable rock layer (such as sandstone) receives water along its outcrop at a level higher than the level of the surface of the ground at the well site. At the outcrop the water moves down into the aquifer (water-bearing layer) but is prevented from leaving it, by impermeable rock layers (such as shale) above and below it. Pressure from the water’s weight (hydrostatic pressure) forces water to the surface of a well drilled down into the aquifer; the pressure for the steady upflow is maintained by the continuing penetration of water into the aquifer at the intake area.

In places where the overlying impermeable rocks are broken by joints or faults, water may escape through them to rise to the surface as artesian springs. In some areas, artesian wells and springs are a major source of water, especially in arid plains adjacent to mountain ranges that receive precipitation. The rapid development of new wells through over-drilling, however, has tended to reduce head pressures in many artesian systems. As a result, most artesian wells are now outfitted with pumps.

An artesian well may sound like a fancy place to get your water, but it’s really nothing more than a well tapping groundwater that is under pressure. In some artesian wells, the pressure is high enough that a pump isn’t needed to bring water to the surface. These wells are known as flowing artesian wells.

Artesian wells occur naturally over large areas of the Santa Clara Valley, and flowing artesian wells have been observed since the 1850s. When pressures in groundwater aquifers are high, old lost wells may begin flowing freely at the land surface. This wastes water and can create nuisance conditions. Recent wet winters and low groundwater pumping are causing higher pressures in artesian aquifers. This is causing more old wells to start flowing and leading to more frequent discoveries of old abandoned wells.

Whether they are flowing or not, the problem with abandoned wells is they can provide a way for contaminants to move into groundwater or between groundwater aquifers. That’s why they’re not allowed by state law or Valley Water ordinance.

Groundwater is a key source of water for Santa Clara County – our groundwater basins can hold more water than all 10 of our surface water reservoirs combined – and Valley Water works hard to protect the quality of this water that is so important to life in our county.

All wells that are no longer in use must be properly destroyed to avoid groundwater contamination. Artesian wells are the responsibility of the property owner where the well is found.

If you see a lot of water on the ground, how do you know if it’s coming from an artesian well?

Things to look for:

(a) Water at the land surface with no known source: it’s not leaking from pipes; it’s not from shallow groundwater (usually found in low spots on freeways, during excavation or in basements, etc.); and it’s not from a spring (typically found on or at the base of a hill slope);

(b) There may be bubbles in the water;

(c) You actually see water emanating from a well.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1064 2021-06-28 00:14:21

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

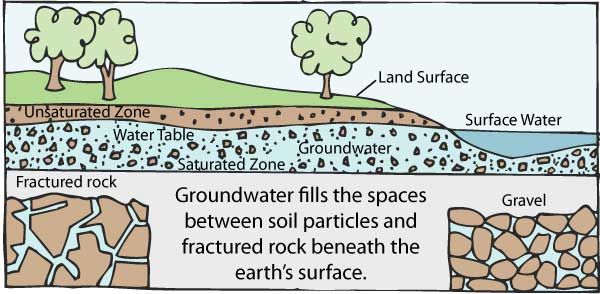

1042) Groundwater

Groundwater, water that occurs below the surface of Earth, where it occupies all or part of the void spaces in soils or geologic strata. It is also called subsurface water to distinguish it from surface water, which is found in large bodies like the oceans or lakes or which flows overland in streams. Both surface and subsurface water are related through the hydrologic cycle (the continuous circulation of water in the Earth-atmosphere system).

A brief treatment of groundwater follows.

Most groundwater comes from precipitation. Precipitation infiltrates below the ground surface into the soil zone. When the soil zone becomes saturated, water percolates downward. A zone of saturation occurs where all the interstices are filled with water. There is also a zone of aeration where the interstices are occupied partially by water and partially by air. Groundwater continues to descend until, at some depth, it merges into a zone of dense rock. Water is contained in the pores of such rocks, but the pores are not connected and water will not migrate. The process of precipitation replenishing the groundwater supply is known as recharge. In general, recharge occurs only during the rainy season in tropical climates or during winter in temperate climates. Typically, 10 to 20 percent of the precipitation that falls to the Earth enters water-bearing strata, which are known as aquifers.

Groundwater is constantly in motion. Compared to surface water, it moves very slowly, the actual rate dependent on the transmissivity and storage capacity of the aquifer. Natural outflows of groundwater take place through springs and riverbeds when the groundwater pressure is higher than atmospheric pressure in the vicinity of the ground surface. Internal circulation is not easily determined, but near the water table the average cycling time of water may be a year or less, while in deep aquifers it may be as long as thousands of years.

Groundwater plays a vital role in the development of arid and semiarid zones, sometimes supporting vast agricultural and industrial enterprises that could not otherwise exist. It is particularly fortunate that aquifers antedating the formation of deserts remain unaffected by increases in aridity with the passage of time. Withdrawal, however, will deplete even the largest of groundwater basins so that development based on the existence of aquifers can be only temporary at best.

A vast amount of groundwater is distributed throughout the world, and a large number of groundwater reservoirs are still underdeveloped or uninvestigated. Scientists estimate that some 5.97 quintillion gallons (22.6 million cubic km [5.4 million cubic miles]) of groundwater reside in the upper 2 km (1.2 miles) of Earth’s surface. The most frequently investigated or exploited groundwater reservoirs are of the unconsolidated clastic (mainly sand and gravel) or carbonate hardrock type found in alluvial valleys and coastal plains under temperate or arid conditions.

Though some groundwater dissolves substances from rocks and may contain traces of old seawater, most groundwater is free of pathogenic organisms, and purification for domestic or industrial use is not necessary. Furthermore, groundwater supplies are not seriously affected by short droughts and are available in many areas that do not have dependable surface water supplies. However, aquifers and other groundwater supplies are at risk of chemical pollution from fracking, agricultural chemicals, leaking or unfit landfills and septic tanks, and other point and nonpoint sources of pollution. Such contamination can render groundwater unfit for use and is expensive and difficult to clean up.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1065 2021-06-29 00:03:40

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1043) Public utility

Public utility, enterprise that provides certain classes of services to the public, including common carrier transportation (buses, airlines, railroads, motor freight carriers, pipelines, etc.); telephone and telegraph; power, heat, and light; and community facilities for water, sanitation, and similar services. In most countries such enterprises are state-owned and state-operated, but in the United States they are mainly privately owned and are operated under close governmental regulation.

The classic explanation for the need to regulate public utilities is that they are enterprises in which the technology of production, transmission, and distribution almost inevitably leads to complete or partial monopoly—that they are, in a phrase, natural monopolies. The monopolistic tendency arises from economies of scale in the particular industry, from the large capital costs typical of such enterprises, from the inelasticity of demand among consumers of the service, from considerations of the excess capacity necessary to meet demand peaks, and other considerations. It is often also the case that the existence of competing parallel systems—of local telephones or natural gas, for example—would be inordinately expensive, wasteful, and inconvenient. Given the tendency to monopoly and the potential therefore of monopolistic pricing practices, public regulation has for more than a century been applied to certain classes of business.

In practice, regulation aims to ensure that the utility serves all who apply for and are willing and able to pay for its services, that it operates in a safe and adequate manner, that it serves all customers on equal terms, and that its rates are just and reasonable. All states have regulatory commissions, and the federal government has several, including the Interstate Commerce Commission, the Civil Aeronautics Board, the Federal Power Commission, the Federal Communications Commission, and the Securities and Exchange Commission.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1066 2021-06-30 00:22:24

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1044) Radio and radar astronomy

Radio and radar astronomy, study of celestial bodies by examination of the radio-frequency energy they emit or reflect. Radio waves penetrate much of the gas and dust in space, as well as the clouds of planetary atmospheres, and pass through Earth’s atmosphere with little distortion. Radio astronomers can therefore obtain a much clearer picture of stars and galaxies than is possible by means of optical observation. The construction of ever larger antenna systems and radio interferometers and improved radio receivers and data-processing methods have allowed radio astronomers to study fainter radio sources with increased resolution and image quality.

In 1932 the American physicist Karl Jansky first detected cosmic radio noise from the centre of the Milky Way Galaxy while investigating radio disturbances that interfered with transoceanic telephone service. (The radio source at the centre of the Galaxy is now known as Sagittarius A.) The American amateur radio operator Grote Reber later built the first radio telescope at his home in Wheaton, Ill., and found that the radio radiation came from all along the plane of the Milky Way and from the Sun. For the first time, astronomers could observe objects in a new region of the electromagnetic spectrum outside that of visible light.

During the 1940s and ’50s, Australian and British radio scientists were able to locate a number of discrete sources of celestial radio emission that they associated with old supernovae (Taurus A, identified with the Crab Nebula) and active galaxies (Virgo A and Centaurus A) that later became to be known as radio galaxies.

In 1951, American physicists Harold Ewen and E.M. Purcell detected 21-cm radiation emitted by cold clouds of interstellar hydrogen atoms. This emission was later used to define the spiral arms of the Milky Way Galaxy and to determine the rotation of the Galaxy.

In the 1950s, astronomers at Cambridge University published three catalogs of astronomical radio sources. The last of these, the Third Cambridge Catalogue (or 3C), published in 1959, contained some sources, most notably 3C 273, that were identified with faint stars. In 1963 American astronomer Maarten Schmidt observed 3C 273 with an optical telescope and found that it was not a star in the Milky Way Galaxy but a very distant object nearly two billion light-years from Earth. Objects like 3C 273 were called quasi-stellar radio sources, or quasars.

Beginning in the late 1950s, radio studies of the planets revealed the existence of a greenhouse effect on Venus, intense Van Allen radiation belts surrounding Jupiter, powerful radio storms in Jupiter’s atmosphere, and an internal heating source deep within the interiors of Jupiter and Saturn.

Radio telescopes are also used to study interstellar molecular gas clouds. The first molecule detected by radio telescopes was hydroxyl (OH) in 1963. Since then about 150 molecular species have been detected, only a few of which can be observed at optical wavelengths. These include carbon monoxide, ammonia, water, methyl and ethyl alcohol, formaldehyde, and hydrogen cyanide, as well as some heavy organic molecules such as the amino acid glycine.

In 1964, Bell Laboratories scientists Robert Wilson and Arno Penzias detected the faint cosmic microwave background (CMB) signal left over from the original big bang, thought to have occurred 13.8 billion years ago. Subsequent observations of this CMB in the 1990s and 2000s with the Cosmic Background Explorer and the Wilkinson Microwave Anisotropy Probe satellites have detected fine-scale deviations from the smooth background that correspond to the initial formation of structure in the early universe.

Radio observations of quasars led to the discovery of pulsars (or pulsating radio stars) by British astronomers Jocelyn Bell and Antony Hewish in Cambridge, Eng., in 1967. Pulsars are neutron stars that spin very rapidly, up to nearly 1,000 times per second. Their radio emission is concentrated along a narrow cone, producing a series of pulses corresponding to the rotation of the neutron star, much like the beacon from a rotating lighthouse lamp. In 1974, using the Arecibo Observatory, American astronomers Joseph Taylor and Russell Hulse observed a binary pulsar (two pulsars in orbit around each other) and found that their orbital period was decreasing because of gravitational radiation at exactly the rate predicted by Albert Einstein’s theory of general relativity.

Using powerful radar systems, it is possible to detect radio signals reflected from nearby astronomical bodies such as the Moon, the nearby planets, some asteroids and comets, and the larger moons of Jupiter. Precise measurements of the time delay between the transmitted and reflected signal and the spectrum of the returned signal are used to precisely measure the distance to solar system objects and to image their surface features with a resolution of a few metres. The first successful detection of radar signals from the Moon occurred in 1946. This was quickly followed by experiments in the United States and the Soviet Union using powerful radar systems built for military and commercial applications. Both radio and radar studies of the Moon revealed the sandlike nature of its surface even before the Apollo landings were made. Radar echoes from Venus have penetrated its dense cloud cover surrounding the surface and have uncovered valleys and enormous mountains on the planet’s surface. The first evidence for the correct rotation periods of Venus and of Mercury also came from radar studies.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1067 2021-07-01 00:25:08

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1045) Mercury (chemical element)

Mercury (Hg), also called quicksilver, chemical element, liquid metal of Group 12 (IIb, or zinc group) of the periodic table.

Element Properties :

atomic number : 80

atomic weight : 200.59

melting point : −38.87 °C (−37.97 °F)

boiling point : 356.9 °C (674 °F)

specific gravity : 13.5 at 20 °C (68 °F)

valence : 1, 2

Properties, Uses, And Occurrence

Mercury was known in Egypt and also probably in the East as early as 1500 BCE. The name mercury originated in 6th-century alchemy, in which the symbol of the planet was used to represent the metal; the chemical symbol Hg derives from the Latin hydrargyrum, “liquid silver.” Although its toxicity was recognized at an early date, its main application was for medical purposes.

Mercury is the only elemental metal that is liquid at room temperature. (Cesium melts at about 28.5 °C [83 °F], gallium at about 30 °C [86 °F], and rubidium at about 39 °C [102 °F].) Mercury is silvery white, slowly tarnishes in moist air, and freezes into a soft solid like tin or lead at −38.87 °C (−37.97 °F). It boils at 356.9 °C (674 °F).

It alloys with copper, tin, and zinc to form amalgams, or liquid alloys. An amalgam with silver is used as a filling in dentistry. Mercury does not wet glass or cling to it, and this property, coupled with its rapid and uniform volume expansion throughout its liquid range, makes it useful in thermometers. Barometers and manometers utilize its high density and low vapour pressure. Gold and silver dissolve readily in mercury, and in the past this property was used in the extraction of these metals from their ores.

The good electrical conductivity of mercury makes it exceptionally useful in sealed electrical switches and relays. An electrical discharge through mercury vapour contained in a fused silica tube or bulb produces a bluish glow rich in ultraviolet light, a phenomenon exploited in ultraviolet, fluorescent, and high-pressure mercury-vapour lamps. Mercury’s high thermal neutron-capture cross section (360 barns) and good thermal conductivity make it applicable as a shield and coolant in nuclear reactors. Much mercury is utilized in the preparation of pharmaceuticals and agricultural and industrial fungicides.

The use of mercury in the manufacture of chlorine and caustic soda (sodium hydroxide) by electrolysis of brine depends upon the fact that mercury employed as the negative pole, or cathode, dissolves the sodium liberated to form a liquid amalgam. An interesting application, though not of great commercial significance, is the use of mercury vapour instead of steam in some electrical generating plants, the higher boiling point of mercury providing greater efficiency in the heat cycle.

Mercury occurs in Earth’s crust on the average of about 0.08 gram (0.003 ounce) per ton of rock. The principal ore is the red sulfide, cinnabar. Native mercury occurs in isolated drops and occasionally in larger fluid masses, usually with cinnabar, near volcanoes or hot springs. Over two-thirds of the world supply of mercury comes from China, with most of the remainder coming from Kyrgyzstan and Chile; it is often a by-product of gold mining. Cinnabar is mined in shaft or open-pit operations and refined by flotation. Most of the methods of extraction of mercury rely on the volatility of the metal and the fact that cinnabar is readily decomposed by air or by lime to yield the free metal. Because of the toxicity of mercury and the threat of rigid pollution control, attention is being directed toward safer methods of extracting mercury. These generally rely on the fact that cinnabar is readily soluble in solutions of sodium hypochlorite or sulfide, from which the mercury can be recovered by precipitation with zinc or aluminum or by electrolysis.

Extremely rare natural alloys of mercury have also been found: moschellandsbergite (with silver), potarite (with palladium), and gold amalgam. Mercury is extracted from cinnabar by roasting it in air, followed by condensation of the mercury vapour. Mercury is toxic. Poisoning may result from inhalation of the vapour, ingestion of soluble compounds, or absorption of mercury through the skin.

Natural mercury is a mixture of seven stable isotopes: 196Hg (0.15 percent), 198Hg (9.97 percent), 199Hg (16.87 percent), 200Hg (23.10 percent), 201Hg (13.18 percent), 202Hg (29.86 percent), and 204Hg (6.87 percent). As a wavelength standard and for other precise work, isotopically pure mercury consisting of only mercury-198 is prepared by neutron bombardment of natural gold, gold-197.

Principal Compounds

The compounds of mercury are either of +1 or +2 oxidation state. Mercury(II) or mercuric compounds predominate. Mercury does not combine with oxygen to produce mercury(II) oxide, HgO, at a useful rate until heated to the range of 300 to 350 °C (572 to 662 °F). At temperatures of about 400 °C (752 °F) and above, the reaction reverses with the compound decomposing into its elements. Antoine-Laurent Lavoisier and Joseph Priestley used this reaction in their study of oxygen.

There are relatively few mercury(I) or mercurous compounds. The mercury(I) ion, Hg22+, is diatomic and stable. Mercury(I) chloride, Hg2Cl2 (commonly known as calomel), is probably the most important univalent compound. It is used in antiseptic salves. Mercury(II) chloride, HgCl2 (also called bichloride of mercury or corrosive sublimate), is perhaps the commonest bivalent compound. Although extremely toxic, this odourless, colourless substance has a wide variety of applications. In agriculture it is used as a fungicide; in medicine it is sometimes employed as a topical antiseptic in concentrations of one part per 2,000 parts of water; and in the chemical industry it serves as a catalyst in the manufacture of vinyl chloride and as a starting material in the production of other mercury compounds. Mercury(II) oxide, HgO, provides elemental mercury for the preparation of various organic mercury compounds and certain inorganic mercury salts. This red or yellow crystalline solid is also used as an electrode (mixed with graphite) in zinc-mercuric oxide electric cells and in mercury batteries. Mercury(II) sulfide, HgS, is a black or red crystalline solid used chiefly as a pigment in paints, rubber, and plastics.

It appears to me that if one wants to make progress in mathematics, one should study the masters and not the pupils. - Niels Henrik Abel.

Nothing is better than reading and gaining more and more knowledge - Stephen William Hawking.

Offline

#1068 2021-07-02 00:43:04

- Jai Ganesh

- Administrator

- Registered: 2005-06-28

- Posts: 52,952

Re: Miscellany

1046) Tungsten processing

Tungsten processing, preparation of the ore for use in various products.

Tungsten exhibits a body-centred cubic (bcc) crystal lattice. It has the highest melting point of all metals, 3,410° C (6,170° F), and it has high conductivity for electricity. Owing to this unique combination of properties, it is used extensively as filaments for incandescent lamps, as electric contacts, and as electron emitters for electronic devices. Tungsten also has found wide application as an alloying element for tool steels and wear-resistant alloys. Tungsten carbides are used for cutting tools and hard-facing materials owing to their hardness and resistance to wear. The metal is brittle at room temperature but ductile and strong at elevated temperatures. Its alloys are employed in rocket-engine nozzles and other aerospace applications.

History

Tungsten in one of its mineral forms was given its name (meaning “heavy stone”) by the Swedish mineralogist A.F. Cronstedt in 1755. In 1781 another Swede, Carl Wilhelm Scheele, analyzed the mineral and identified lime and an acid that he called tungstic acid; the mineral was later named scheelite. In 1783 the Spanish chemists Juan José and Fausto Elhuyar obtained metallic tungsten by the reduction of its oxide with carbon; it was named wolfram (hence its chemical symbol, W) for the mineral wolframite, from which it was extracted. In 1847, Robert Oxland patented in Britain his manufacturing process for sodium tungstate, tungstic acid, and the pure metal, and in 1857, he patented his process for producing tungsten steel. But it was not until 1908, when William David Coolidge obtained his British patent for producing ductile tungsten wire, that the filament industry began. Tungsten-containing high-speed tool steel came to public attention when the Bethlehem Steel Company exhibited its products at the Exposition Universelle of 1900 in Paris. In 1927 the Krupp Laboratory at Essen, Ger., discovered that a serviceable product could be produced when the normally brittle tungsten carbide was mixed with a cemented material.

Ores

Major minerals of tungsten are essentially of two categories. The first is wolframite [(Fe, Mn)WO4], which contains iron and manganese tungstates in all proportions between 20 and 80 percent of each. The second is scheelite (CaWO4), which fluoresces a bright bluish colour under ultraviolet light.

Tungsten deposits occur in association with metamorphic rocks and granitic igneous rocks. The most important mines are in the Nan Mountains in the Kiangsi, Hunan, and Kwangtung provinces of China, which possesses about 50 percent of the world’s reserves. In Russia, mines are located in the northern Caucasus and around Lake Baikal. There are also deposits in Kazakhstan. About 90 percent of South Korea’s tungsten is at Sang Dong. Canada’s Northwest Territories is home to the largest tungsten mine in the Western world, and a mine at Chojlla, Bol., is the largest producer in South America. Deposits in the United States are spread along the Rocky Mountains.

Mining And Concentrating

The Nan Mountains deposits are principally high-grade wolframite veins that are found outcropping in great numbers in many separate areas. These conditions are favourable for exploitation by small-scale operations. Open-pit methods have been used in Australia and Canada, while underground mining is generally necessary for other mines in the world.

Tungsten ores are beneficiated by crushing followed by gravity concentration. Flotation separation is used for scheelite that has been ground to a fine size to liberate the tungsten; this is further supplemented by leaching, roasting, and magnetic or high-tension separation when required.

Extraction And Refining

Ammonium paratungstate

Tungsten ores frequently occur in association with sulfides and math, which can be removed by roasting in air for two to four hours at 800° C (1,450° F). In order to produce ammonium paratungstate (APT), an intermediate compound in production of the pure metal, ores may be decomposed by acid leaching or by the autoclave-soda process. In the latter process, the ground ore is maintained for 11/2 to 4 hours in a solution of 10–18 percent sodium carbonate at temperatures of 190° to 230° C (375° to 445° F) and under a pressure of 14.1–24.6 kilograms per square centimetre (200–350 pounds per square inch). Prior to the removal of unreacted gangue by filtration, the acidity is adjusted to pH 9–9.5, and aluminum and manganese sulfates are added at 70°–80° C (160°–175° F) and stirred for one hour. This can eliminate phosphorus and math and reduce silica to a level of 0.03–0.06 percent. Molybdenum is removed by adding sodium sulfide at 80°–85° C (175°–185° F) at a pH of 10, holding for one hour, and then acidifying the solution to pH 2.5–3 and stirring for seven to nine hours to precipitate molybdenum sulfide. The remaining sodium tungstate solution can be further purified by a liquid ion-exchange process, using an organic extractant consisting of 7 percent alamine-336, 7 percent decanol, and 86 percent kerosene. During the countercurrent flow of the extractant through the solution, tungstate ions transfer from the aqueous phase to the organic phase. The tungsten is then stripped from the extractant into an ammonia solution containing ammonium tungstate. The resultant APT solution is sent to an evaporator for crystallization.

In the acid-leaching process, scheelite concentrate is decomposed by hydrochloric acid in the presence of sodium nitrate as an oxidizing agent. This charge is agitated by steam spraying and is maintained at 70° C (160° F) for 12 hours. The resultant slurry, containing tungsten in the form of a solid tungstic acid, is diluted and allowed to settle. The tungstic acid is then dissolved in aqueous ammonia at 60° C (140° F) for two hours under stirring. Calcium from the resulting solution is precipitated as calcium oxalate, while phosphorus and math may be removed by the addition of magnesium oxide, which forms insoluble phosphates and math of ammonium and magnesium. Iron, silica, and similar impurities that form colloidal hydroxides are removed by adding a small amount of activated carbon and digesting for one to two hours. The solution is clarified through pressure filters and evaporated to obtain APT crystals.